Levulinic acid

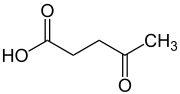

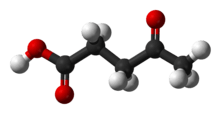

Levulinic acid, or 4-oxopentanoic acid, is an organic compound with the formula CH3C(O)CH2CH2CO2H. It is classified as a keto acid. This white crystalline solid is soluble in water and polar organic solvents. It is derived from degradation of cellulose and is a potential precursor to biofuels,[2] such as ethyl levulinate.[3]

| |

| |

| Names | |

|---|---|

| IUPAC name

4-Oxopentanoic acid | |

| Other names

Levulinic acid, β-Acetylpropionic acid, 3-Acetopropionic acid, β-acetylpropionic acid, γ-ketovaleric acid, 4-oxopentanoic acid | |

| Identifiers | |

3D model (JSmol) |

|

| ChEBI | |

| ChEMBL | |

| ChemSpider | |

| DrugBank | |

| ECHA InfoCard | 100.004.228 |

PubChem CID |

|

| UNII | |

CompTox Dashboard (EPA) |

|

| |

| |

| Properties | |

| C5H8O3 | |

| Molar mass | 116.11 g/mol |

| Density | 1.1447 g/cm3 |

| Melting point | 33 to 35 °C (91 to 95 °F; 306 to 308 K) |

| Boiling point | 245 to 246 °C (473 to 475 °F; 518 to 519 K) |

Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa). | |

| Infobox references | |

History

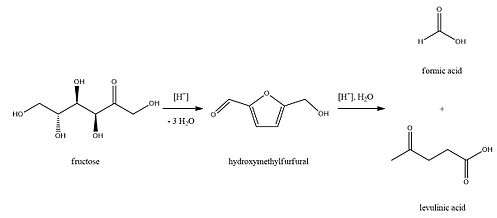

In 1840 the Dutch professor Gerardus Johannes Mulder mentioned levulinic acid for the first time.[4] He synthesized it by heating fructose with hydrochloric acid. The former term “levulose” for fructose gave levulinic acid its name. Although levulinic acid has been well known since the 1870s, it has never reached a commercial use in significant volume. First commercial production of levulinic acid began as a batchwise process in an autoclave by A.E. Statley in the 1940s.[5] In 1953 the US company Quaker Oats developed a continuous process for the production of levulinic acid.[6] In 1956 it was identified as a platform chemical with high potential[7] and in 2004 the US Department of Energy (U.S. DoE) identified levulinic acid by screening approximately 300 substances as one of the 12 potential platform chemicals in the biorefinery concept.[8]

Synthesis

The original synthesis of levulinic acid is done by heating hexoses (glucose, fructose) or starch in dilute hydrochloric acid or sulfuric acid.[4][9][10] The yield depends on the nature of the acid, acid concentration, temperature and pressure.[11] In addition to formic acid further, partly insoluble, by-products are produced. These are deeply colored and their complete removal is a challenge for most technologies.

Many concepts for the commercial production of levulinic acid are based on a strong acid technology. The processes are conducted in a continuous manner using lignocellulose as inexpensive starting material which is impregnated by dilute mineral acid and transferred to a high pressure reactor where it is heated with steam to allow the reaction to form levulinic acid to take place. After cooling the reaction mixture and filtering off the solid by-products, the levulinic acid that is formed is separated from the mineral acid catalyst by extraction without neutralization of the acid catalyst. This allows the acid catalyst to be recycled, while the levulinic acid can be purified from the acid-free organic solvent. Pure levulinic acid is isolated by evaporation of the extraction solvent and distillation of the levulinic acid. Companies who developed technology based on this concept include Biofine,[12] DSM,[13] Segetis,[14] and GFBiochemicals. GFBiochemicals started the commercial production of levulinic acid in 2015 at a production scale of 2,000 MT/a in Caserta, Italy.[15][16] 2Caserta is the world's largest operational production plant for levulinic acid.[16]

Reactions and applications

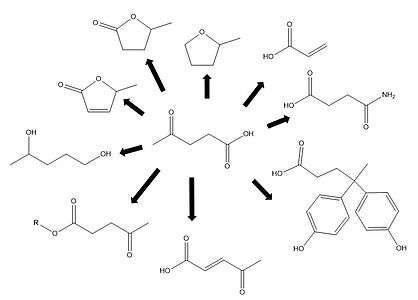

Levulinic acid is used as a precursor for pharmaceuticals, plasticizers, and various other additives.[17] The largest application of levulinic acid is its use in the production of aminolevulinic acid, a biodegradable herbicide used in South Asia. Another key application is the use of levulinic acid in cosmetics. Ethyl levulinate, a primary derivative of levulinic acid, is extensively used in fragrances and perfumes. Levulinic acid is a chemical building block or starting material for a wide variety of other compounds[18] including γ-valerolactone and 2-methyl-THF.[8]

Other occurrence and niche uses

Levulinic acid is used in cigarettes to increase nicotine delivery in smoke and binding of nicotine to neural receptors.[19]

Safety

Levulinic acid is relatively nontoxic, with an LD50 of 1850 mg/kg.[17]

References

- The Merck Index, 15th Ed. (2013), p. 1018, Monograph 5526, O'Neil: The Royal Society of Chemistry. Available online at: http://www.rsc.org/Merck-Index/monograph/mono1500005526

- Biorefineries – Industrial Processes and Products. Status Quo and Future Directions. Vol. 1, Edited by Birgit Kamm, Patrick R. Gruber, Michael Kamm. 2006, WILEY-VCH, Weinheim. ISBN 3-527-31027-4

- Leal Silva, Jean Felipe; Grekin, Rebecca; Mariano, Adriano Pinto; Maciel Filho, Rubens (2018). "Making Levulinic Acid and Ethyl Levulinate Economically Viable: A Worldwide Technoeconomic and Environmental Assessment of Possible Routes". Energy Technology. 6 (4): 613–639. doi:10.1002/ente.201700594. ISSN 2194-4296.

- Mulder, G. J. (1840). "Untersuchungen über die Humussubstanzen" [Investigations on humic substances]. J. Prakt. Chem. (in German). 21 (1): 203–240. doi:10.1002/prac.18400210121.

- A.E.Staley, Mfg.Co.A.E.(DecaturIll.); LevulinicAcid 1942 [C.A. 36, 1612]

- US-2813900 (1953)

- R.H.Leonard, Ind. Eng. Chem. 1331, (1956).

- "Top Value Added Chemicals from Biomass: Volume I--Results of Screening for Potential Candidates from Sugars and Synthesis Gas" (PDF).

- A. Freiherrn, V. Grote, B. Tollens, "Untersuchungen über Kohlenhydrate. I. Ueber die bei Einwirkung von Schwefelsäure auf Zucker entstehende Säure (Levulinsäure)" Justus Liebigs Annalen der Chemie volume 175, pp. 181-204 (1875). doi: 10.1002/jlac.18751750113

- B. F. McKenzie (1941). "Levulinic acid". Organic Syntheses.; Collective Volume, 1, p. 335

- S.L. Suib, New and Future Developments in Catalysis – Catalytic Biomass Conversion, Elsevier, (2013). ISBN 978-0-444-53878-9

- US-5608105

- WO-2014087016 A1

- US-20140128634

- "Commercial-scale production for bio-based levulinic acid - Chemical Engineering | Page 1".

- "GFBiochemicals reaches commercial-scale in renewable levulinic acid project : Biofuels Digest".

- Franz Dietrich Klingler, Wolfgang Ebertz "Oxocarboxylic Acids" in Ullmann's Encyclopedia of Industrial Chemistry, 2005, Wiley-VCH, Weinheim. doi:10.1002/14356007.a18_313

- Bozell, Joseph J.; Petersen, Gene R. (2010-04-06). "Technology development for the production of biobased products from biorefinery carbohydrates—the US Department of Energy's "Top 10" revisited". Green Chemistry. 12 (4): 539–554. doi:10.1039/b922014c.

- Doris Cullen et al., A Guide to Deciphering the Internal Codes Used by the Tobacco Industry, Report No. 03-05, Harvard School of Public Health, Division of Public Health Practice, Tobacco Research Program, August 2005, http://legacy.library.ucsf.edu/resources/harvard_monograph.pdf

- Dunstan, Wyndham Rowland (1911). . In Chisholm, Hugh (ed.). Encyclopædia Britannica. 23 (11th ed.). Cambridge University Press. p. 802.