Cyfarthfa Ironworks

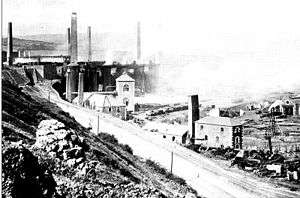

The Cyfarthfa Ironworks was a major 18th- and 19th-century ironworks in Cyfarthfa, on the north-western edge of Merthyr Tydfil, in South West Wales.

The beginning

The Cyfarthfa works were begun in 1765 by Anthony Bacon (by then a merchant in London), who in that year with William Brownrigg, a fellow native of Whitehaven, Cumberland, leased the right to mine in a tract of 4,000 acres (16 km2) land on the west side of the river Taff at Merthyr Tydfil.[1] They employed Brownrigg's brother-in-law Charles Wood to build a forge there, to use the potting and stamping process, for which he and his brother had a patent. This was powered by water from the river, the race dividing into six to power a clay mill (for making the pots), two stampers, two helve hammers and a chafery. The construction of the first coke blast furnace began in August 1766. This was intended to be 50 feet high with cast iron blowing cylinders, rather than the traditional bellows. It was probably brought into blast in autumn 1767.[2] In the meantime, Plymouth ironworks was leased to provide pig iron for the forge.[3]

Brownrigg retired as a partner in 1777, receiving £1500 for his share.[4] From about that time Richard Crawshay was Bacon's partner in his contracts to supply cannon to the Board of Ordnance, but perhaps not in the ironworks. Bacon had previously subcontracted cannon-founding to John Wilkinson, but henceforth made them at Cyfarthfa, as is indicated by his asking for ships carrying them to be convoyed from Penarth.[5] Bacon had the Cyfarthfa Canal, a short tub boat waterway, constructed during the latter part of the 1770s to bring coal to the ironworks.[6]

In 1782, Bacon (as a Member of Parliament) had to give up government contracts and passed the forge and boring mill with the gunfounding business to Francis Homfray. However, he gave it up in 1784 to David Tanner, so that his sons could establish the Penydarren Ironworks. However, David Tanner also did not stay long, giving up the works in 1786, the year of Bacon's death. Tanner's managers were James Cockshutt, Thomas Treharne, and Francis William Bowzer.

Bacon left a family of illegitimate children and was the subject of Chancery proceedings. The court directed a lease of the whole works to Richard Crawshay, who took as his partners, William Stevens (a London merchant) and James Cockshutt. Richard Crawshay took out a licence from Henry Cort for the use of his puddling process, and proceeded to build the necessary rolling mill. However, difficulties remained with the puddling process and it was not until perhaps 1791 that these were resolved. In 1890, Crawshay terminated the partnership, which had been barely profitable, and continued the works alone, adding further furnaces in the following years.

The Crawshay heyday

Robert Thompson Crawshay 1739–1810

.jpg)

Under Richard Crawshay, the Cyfarthfa works rapidly became an important producer of iron products. Great Britain was involved in various naval conflicts during this time around the British Empire, and the demand for cannon and other weapons was great. Cyfarthfa works became critical to the success of the war effort, so much so that Admiral Nelson paid a personal visit to the works in 1802.[7] The Crawshay family crest included a pile of cannonballs in token of the crucial role of their ironworks. Richard passed on the responsibility for the works to his son, William, but the latter was less committed to the works than his father.[7]

William Crawshay II 1788–1867

William Crawshay II was appointed by his father William Crawshay to manage the works after Richard's death in 1810. By 1819, the ironworks had grown to six blast furnaces, producing 23,000 tons of iron. The works continued to play an enormous role in providing high-quality iron to fuel the voracious appetite of the Industrial Revolution, with the Tsar of Russia sending a representative to view the production of iron rail. During this time, the Cyfarthfa works lost its position as the leading ironworks in Merthyr Tydfil to its longtime rival, the Dowlais Ironworks.

It was also during this period that Crawshay had built a home, which became known as Cyfarthfa Castle. The buildings were erected in 1824, at a cost of £30,000 (equivalent to £2,104,964.72 in 2007[8]). They were solidly and massively built of local stone, and designed by Robert Lugar, the same engineer who had built many bridges and viaducts for the local railways. It was designed in the form of a "sham" or mock castle, complete with crenellated battlements, towers and turrets, in Norman and Gothic styles, and occupied by William Crawshay II and his family. It stood, and still does, amid 158 acres (0.64 km2) of landscaped parkland, and overlooked the family-owned ironworks just across the river. The Cyfarthfa Canal ceased operation in the late 1830s during William Crawshay II's time as manager.[9]

Robert Thompson Crawshay 1847–1879

Robert Thompson Crawshay was the last of the great Crawshay ironmasters, as foreign competition and the rising cost of iron ore (much of which had to be imported as local supplies were exhausted) exacted a heavy toll on the Cyfarthfa works. Robert was reluctant to switch to the production of steel, but in 1875 the works was forced to close.

Decline and final closure

The next generation

After R.T. Crawshay's death, his sons reopened the works,[10] but soon closed again for a long and costly rebuild that was not complete until 1884, while a steel works was constructed.[11] Crawshay Brothers, Cyfarthfa, Limited continued the business until 1902, when the works were sold to Guest Keen and Nettlefolds Limited, the proprietors of the Dowlais Ironworks.[12]

By 1910, the steelworks had been forced to close again, and while it was briefly reopened in 1915 to aid in the production of materials for World War I, the works closed for the last time in 1919. It fell into disrepair until it was dismantled in 1928. The failure of the works was a devastating blow to the local community, as it had depended heavily on the works for its economic livelihood.

The works today

Portions of the enormous complex that formed the Cyfarthfa works remain intact today, including six of the original blast furnaces. The furnaces at Cyfarthfa are the largest and most complete surviving specimens of their type anywhere.[13][14] In 2013, workers building a do-it-yourself store near the site of the old ironworks unearthed a significant portion of the old factory. Found during the excavation were a canal, tram lines and the plant's coking ovens; until the discovery, little was known about how the ironworks prepared its fuel. The structures were razed shortly after the end of World War I. Archaeologists were given an opportunity to study the artifacts before they were reburied.[15][16][17] The site is now part of the Cyfarthfa Heritage Area and is administered by Merthyr Tydfil County Borough Council. The council has plans for restoration of the ironworks site.[18]

See also

- Benjamin Hall

- Pont-y-Cafnau, world's earliest iron railway bridge

- The Fire People, a novel by Alexander Cordell about the lives of the workers at Cyfarthfa and surrounding districts.

- Eliot Crawshay-Williams

References

- L. Ince, The South Wales Iron Industry, 1750–1885 (1993), 60.

- P. Riden, 'Introduction' in J. Gross (ed.), xx–xxiii.

- Ince, 53.

- Ince, 60.

- The National Archives, WO 47/87, 404; WO 47/89, 734; WO47/95, 362 (original pagination).

- "Mining level, Cyfarthfa Canal, Rhyd-y-car, Merthyr Tydfil". Royal Commission on the Ancient and Historical Monuments of Wales. Retrieved 20 August 2018.

- Prior, Neil (21 July 2015). "Merthyr Tydfil's iron revolution celebrated 250 years on". BBC. Retrieved 30 May 2016.

- "Measuring Worth Is a Complicated Question". measuringworth.com. Archived from the original on 19 January 2008. Retrieved 20 August 2018.

- "Cyfarthfa Canal, Merthyr Tydfil". Royal Commission on the Ancient and Historical Monuments of Wales. Retrieved 20 August 2018.

- "Cyfarthfa Ironworks-Lighting the Blast Furnaces-The Re-starting of the Rail Mills". Weekly Mail. 8 November 1879. p. 6. Retrieved 30 May 2016.

- "Steel Making at Cyfarthfa". The Western Mail. 17 May 1884. p. 2. Retrieved 30 May 2016.

- Ince, 64.

- "Blast Furnaces". Cyfarthfa Park and Museum. Retrieved 30 May 2016.

- "Cyfarthfa Ironworks". Cyfarthfa Park and Museum. Retrieved 30 May 2016.

- Prior, Neil (7 September 2013). "Merthyr ironworks: Last chance to visit before burial". BBC. Retrieved 30 May 2016.

- "Merthyr Tydfil iron works exposed by DIY store project". BBC. 21 August 2013. Retrieved 30 May 2016.

- "Merthyr Tydfil iron works discovery open to the public". 6 September 2013. Retrieved 30 May 2016.

- "More Information". Cyfarthfa Park and Museum. Retrieved 30 May 2016.

External links

| Wikimedia Commons has media related to Cyfarthfa Ironworks. |

- Old Merthyr Tydfil: Cyfarthfa Ironworks – Historical Photographs of Cyfarthfa Ironworks.