Clipstone Colliery

Clipstone Colliery was a coal mine situated near the village of the same name on the edge of an area of Nottinghamshire known as “The Dukeries” because of the number of stately homes in the area. The colliery was owned by the Bolsover Colliery Company and was vested in the National Coal Board in 1947. The headstocks and powerhouse are grade II listed buildings.[1]

The headstocks at Clipstone Colliery | |

| Location | |

|---|---|

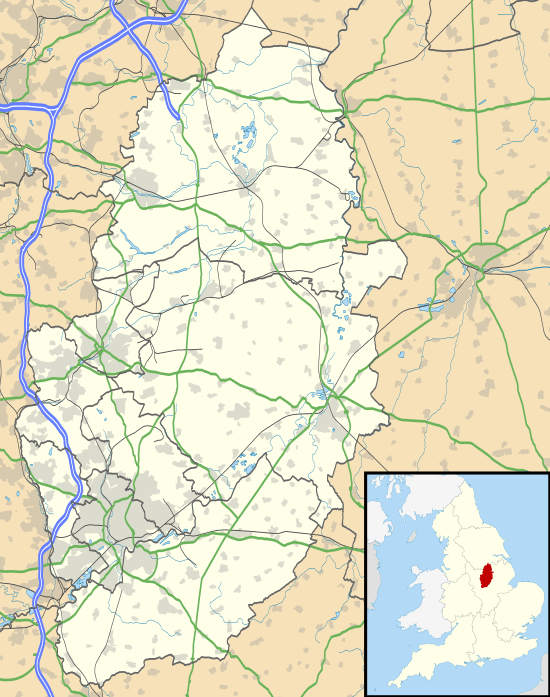

Clipstone Colliery Location in Nottinghamshire | |

| Location | Nottinghamshire |

| County council | Nottinghamshire |

| Country | England |

| Coordinates | 53°09′47″N 1°06′36″W |

| Production | |

| Products | Coal |

| Production | 1 million tons (1986) |

| Greatest depth | 920 metres |

| History | |

| Opened | 1922 |

| Active | 1922 to 2003 |

| Closed | 2003 |

| Owner | |

| Company | Bolsover Colliery Company; British Coal; RJB Mining |

History

The colliery was opened in 1922 to exploit the Barnsley coal seam or “Tophard”, as it is known locally. By the late 1930s it was producing 4,000 tons of coal per day.[1]

The nationalisation of the UK's coal mining industry in 1946, and the establishment of the National Coal Board, led to increased investment in new facilities. As part of this programme Clipstone colliery was expanded to access and exploit the Low Main Seam located about 800 feet (244 m) below the Top Hard seam.[2] The shafts were deepened to over 1000 yards (920 m) to exploit these seams.

Two new headstocks and winding engines were constructed, and were commissioned in 1953. The headstocks, built by Head Wrightson Colliery Engineering were the tallest in Europe at the time. The winding engines, manufactured by Markham and Company, were Koepe friction winders which enabled deeper coal seams to be exploited.[2] Drum winders had traditionally been used in British mines, but were designed to operate at a specific depth and had to be replaced if deeper shafts had to be sunk. One of the shafts at Clipstone was the deepest in Britain.[2] The north or No.1 service shaft was used for personnel and transporting equipment, the south No.2 winding shaft was used to raise coal skips.[1]

Clipstone colliery employed 1,300 people at its peak.[1]

Clipstone colliery was connected to the national railway network via the colliery's four dedicated sidings off the Mansfield branch line.[3] Prior to their closure Thorsby, Welbeck, Ollerton, Bevercotes, Mansfield, Rufford, Blidworth and Blisthorpe collieries and High Marnham power station were also connected to the Mansfield/High Marnham branch lines. The 1,000 MW High Marnham power station was the largest generating station in Europe when it was commissioned in October 1962, and burned around 10,000 tonnes of coal per day, consuming coal from 17 collieries.[4] The branch to Clipstone colliery has since been abolished.[5]

In 1986 Clipstone colliery produced a million tons of coal.[2]

The colliery was closed and mothballed by British Coal, as the National Coal Board had become, in 1993. It was reopened by RJB Mining (now UK Coal) in April 1994, the licence to dig for coal being limited to the Yard seam which is located at a depth of 957 yards (870 m). The colliery was finally closed in April 2003.[2]

The headstocks and winding house were listed in April 2000.[1] The remaining structures on the site are derelict and have been vandalised.[6]

References

- Historic England. "Headstocks and Powerhouse at the site of the former Clipstone Colliery (1380235)". National Heritage List for England. Retrieved 6 June 2015.

- "Clipstone Colliery Coal Mine information". AditNow. Retrieved 5 June 2020.

- Jacobs, Gerald (ed) (1988). Eastern and Anglia Regions Track Diagrams. Exeter: Quail Map Company. p. 12. ISBN 0900609559.CS1 maint: extra text: authors list (link)

- Sheail, John (1991). Power in Trust. Oxford: Clarendon. p. 138. ISBN 0198546734.

- Brailsford, Martyn (ed) (2016). Railway Track Diagrams Book 2 Eastern. Frome: Trackmaps. p. 29. ISBN 9780954986681.CS1 maint: extra text: authors list (link)

- "Report - Clipstone Colliery Headstocks, Notss, October 2018". 28DaysLater.co.uk. October 2018. Retrieved 5 June 2020.