Clemmensen reduction

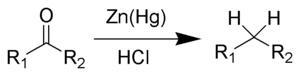

Clemmensen reduction is a chemical reaction described as a reduction of ketones (or aldehydes) to alkanes using zinc amalgam and concentrated hydrochloric acid.[1][2][3] This reaction is named after Erik Christian Clemmensen, a Danish chemist.[4]

| Clemmensen reduction | |

|---|---|

| Named after | Erik Christian Clemmensen |

| Reaction type | Organic redox reaction |

| Identifiers | |

| Organic Chemistry Portal | clemmensen-reduction |

| RSC ontology ID | RXNO:0000038 |

The original Clemmensen reduction conditions are particularly effective at reducing aryl-alkyl ketones,[5][6] such as those formed in a Friedel-Crafts acylation. The two-step sequence of Friedel-Crafts acylation followed by Clemmensen reduction constitutes a classical strategy for the primary alkylation of arenes. With aliphatic or cyclic ketones, modified Clemmensen conditions using activated zinc dust in an anhydrous solution of hydrogen chloride in diethyl ether or acetic anhydride is much more effective.[7]

The substrate must be tolerant of the strongly acidic conditions of the Clemmensen reduction (37% HCl). Several alternatives are available. Acid-sensitive substrates that are stable to strong base can be reduced using the Wolff-Kishner reduction; a further, milder method for substrates stable to hydrogenolysis in the presence of Raney nickel is the two-step Mozingo reduction.

In spite of the antiquity of this reaction, the mechanism of the Clemmensen reduction remains obscure. Due to the heterogeneous nature of the reaction, mechanistic studies are difficult, and only a handful of studies have been disclosed.[8][9] Mechanistic proposals generally invoke organozinc intermediates, sometimes including zinc carbenoids, either as discrete species or as organic fragments bound to the zinc metal surface. However, the corresponding alcohol is believed not to be an intermediate, since subjection of the alcohol to Clemmensen conditions generally does not afford the alkane product.[10]

See also

- Haworth phenanthrene synthesis

- Mozingo reduction

- Wolff-Kishner reduction

References

- Clemmensen, E. (1913). "Reduktion von Ketonen und Aldehyden zu den entsprechenden Kohlenwasserstoffen unter Anwendung von amalgamiertem Zink und Salzsäure". Chemische Berichte. 46 (2): 1837–1843. doi:10.1002/cber.19130460292.

- Clemmensen, E. (1914). "Über eine allgemeine Methode zur Reduktion der Carbonylgruppe in Aldehyden und Ketonen zur Methylengruppe". Chemische Berichte. 47: 51–63. doi:10.1002/cber.19140470108.

- Clemmensen, E. (1914). "Über eine allgemeine Methode zur Reduktion der Carbonylgruppe in Aldehyden und Ketonen zur Methylengruppe. (III. Mitteilung.)". Chemische Berichte. 47: 681–687. doi:10.1002/cber.191404701107.

- Biographies of Chemists, accessed 6 Feb 2007

- "γ-Phenylbutyric acid". Organic Syntheses. 2: 499. 1943.; Vol. 15, p.64 (1935)

- "Creosol". Organic Syntheses. 4: 203. 1963.; Vol. 33, p.17 (1953).

- "Modified Clemmensen Reduction: Cholestane". Organic Syntheses. 6: 289. 1988.; Vol. 53, p.86 (1973).

- Brewster, James H. (2002-05-01). "Reductions at Metal Surfaces. II. A Mechanism for the Clemmensen Reduction 1". Journal of the American Chemical Society. 76 (24): 6364–6368. doi:10.1021/ja01653a035.

- Nakabayashi, Tadaaki (2002-05-01). "Studies on the Mechanism of Clemmensen Reduction. I. The Kinetics of Clemmensen Reduction of p-Hydroxyacetophenone". Journal of the American Chemical Society. 82 (15): 3900–3906. doi:10.1021/ja01500a029.

- Martin, Elmore L. (2004-01-01). "The Clemmensen Reduction". Organic Reactions. John Wiley & Sons,Inc. pp. 155–209. doi:10.1002/0471264180.or001.07. ISBN 9780471264187.

Reviews

- Martin, E. L. (1942). "The Clemmensen reduction". Org. React. 1: 155.

- Buchanan, J. G. St. C.; Woodgate, P. D. (1969). "The Clemmensen reduction of difunctional ketones". Quarterly Reviews, Chemical Society. 23 (4): 522. doi:10.1039/QR9692300522.

- Vedejs, E. (1975). "Clemmensen reduction of ketones in anhydrous organic solvents". Org. React. 22: 401–422.

- Yamamura, S.; Nishiyama, S. (1991). "1.13.2.2 Clemmensen reduction". Comprehensive Organic Synthesis. 8: 309–313.