Aluminium dross recycling

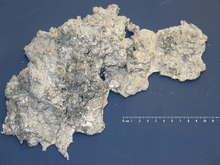

Aluminium dross, a byproduct of the aluminium smelting process, can be mechanically recycled to separate the residual aluminium metal from the aluminium oxide.[1][2]

Thermo-mechanical metal extraction

The mechanical process of recycling does not use any toxic chemicals previously used in the process of extracting the valuable aluminium in the dross.[3]

Hot dross processing system whereby the majority of metal is recovered without chemically reducing the aluminium oxides. The dross is first crushed then separated into aluminium metal rich particles and aluminium oxide rich particles based on density. The metal rich particles are then melted in a furnace to remove the remaining oxide particles.

Mechanical extraction vs chemical

Recycling aluminium dross mechanically is an environmentally sensitive method, and is not toxic. This is completely different from how aluminium metal used to be extracted from dross using an array of hazardous chemicals which resulted in a concentrated highly toxic 'salt cake' residue.[4]

An example of a recycling facility

An operating aluminium dross recycling plant (news coverage) https://www.youtube.com/watch?v=t_z8jlDgdCU[5][6][7]

Products that can be made with the residual

A variety of products can be made from the residual aluminium dross after it is recycled into aluminium oxide. See more information on aluminium oxide.[8] Aluminium oxide has a variety of industrial uses which includes being used in paint, dye, concrete, explosives, and fertilizer.[8][9][10]

Dross recycling is different

Aluminium dross recycling is a completely different process to strictly aluminium recycling. Aluminium recycling is where pure aluminium metal products (previously used in another form) are re-melted into aluminium ingots and then re-used to new aluminium products.[11] While aluminium dross recycling is where the dross, a byproduct of the smelting process in the creation of aluminium from bauxite, can be mechanically recycled thus separating the residual aluminium metal from the aluminium oxide.[12]

References

- "Institute of Materials Processing (IMP) | Materials Science & Engineering" (PDF). Imp.mtu.edu. Retrieved 2014-06-09.

- "Taha Opens Dross Recycling Facility in New Zealand". Azom.com. 2011-10-26. Retrieved 2014-06-09.

- "New Aluminium Dross Recycling Facility in New Zealand". Waste Management World. 2011-10-27. Archived from the original on 2012-05-30. Retrieved 2014-06-09.

- "Dross Processing". Archive.is. 2006-09-26. Archived from the original on 2012-12-09. Retrieved 2014-06-09.

- Scot Mackay (2011-10-06). "Taha Asia Pacific Recycling Plant Opens At Tiwai". Stuff.co.nz. Retrieved 2014-06-09.

- "Dross Recycling Plant - Taha Asia Pacific in New Zealand". YouTube. Retrieved 2014-06-09.

- "Centre a welcome relief". Stuff.co.nz. 2011-10-13. Retrieved 2014-06-09.

- Aluminium oxide

- "Aluminum Oxide". Aluminumsulfate.net. Archived from the original on 2016-12-07. Retrieved 2014-06-09.

- cf Thermite

- cf Aluminium recycling

- http://nzic.org.nz/ChemProcesses/metals/8D.pdf

13. A process to increase the aluminium content of aluminium dross, prior to melting to improve the process economics https://www.ultromex.com/aluminium-dross-recycling.html