Introduction

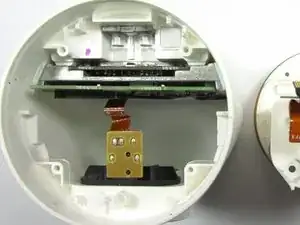

A look inside the ring Stick Up Camera.

Tools

-

-

Features:

-

Inside / Outside, Ceiling / Wall Mounting, Quick Release Battery Pack

-

Night Vision

-

Two Way Talk

-

Adjustable Motion Sensors

-

1080p HD Video

-

115° Field of View

-

2.4GHz Wireless B/G/N WiFi Connectivity

-

-

-

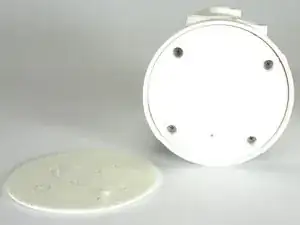

Twist off bottom cover to access PH00 screws

-

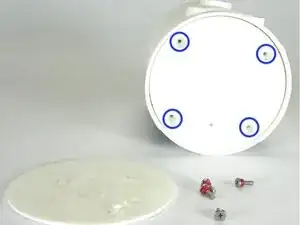

Remove the PH00 screws at the top of the battery compartment.

-

-

-

Remove rubber pad in the battery cover with the Spudger Tool or flat head screwdriver to reveal PH00 screws that hold the battery compartment to the ring camera enclosure. Remove the PH00 screws.

-

-

-

Pry off the top cover with the Spudger Tool or a flat head screwdriver. The top cover pad is glued on and may be hard to pry loose. The top cover is thin, so no need to go to deep to pry off top cover

-

Remove the top cover PH00 screws.

-

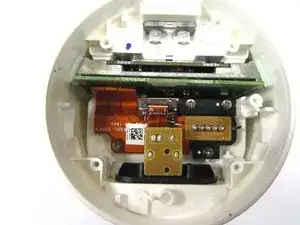

Pry off the top cover to reveal internal electronic components. The top cover is held in place with an O-Ring.

-

-

-

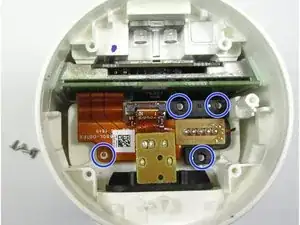

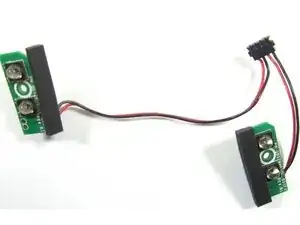

Remove the four PH00 screws that hold the Power and Battery Connector PCBs

-

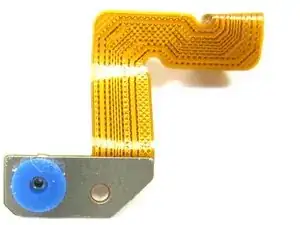

Then, gently, loosen the flex ribbon cables from their connectors with the Spudger Tool, and pull the flex cables away from the connectors.

-

-

-

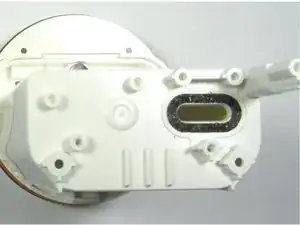

With Spudger Tool, gently press down on the Battery Holder from the topside until it become loose. The Battery Holder, at this step, is held in place via an O-Ring. Once the Battery Holder becomes loose, gently pull it out the rest of way via the bottom of the ring camera enclosure.

-

-

-

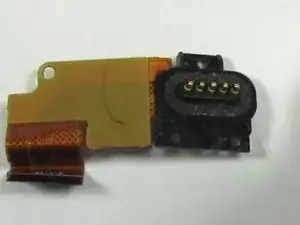

Once the battery holder compartment has been separated from the ring camera enclosure, the battery interface PCB can be pried off the battery holder compartment using the Spudger Tool.

-

-

-

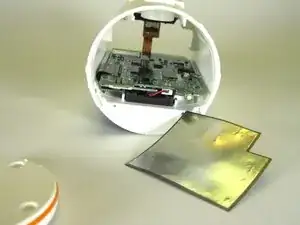

Remove the RF Shield with the Spudger Tool. This can be removed during this step or after the PCB has been removed from the ring camera enclosure. Removing the RF Shield now helps simplify additional steps that may be needed in the teardown.

-

-

-

Loosen the two flex cables by using the Spudger Tool to pry up the flex connector tension strip. Then use the Spudger Tool to pry up the four-wire connector cable. This cable will pop up from the connector

-

-

-

Remove the four PH00 screws holding the PCB in place. Then use the Spudger Tool to gently pry the PCB from the double stick tape holding the PCB.

-

-

-

Remove the two screws on either side of the power connector located on the top back of the ring camera enclosure using the PH2 tool.

-

Then using the Spudger Tool, pop of the rubber covers on either side of the power connector cover in the back, and pry off the power connector cover. This will reveal two PH00 screws that hold the external power interface to ring camera enclosure.

-

Remove the two PH00 screws on either side of the external power connector. Then gently using the Spudger Tool pry the external power connector from the ring camera enclosure.

-

-

-

Use the Opening Pick Tool to remove the face from around the ring camera. Insert the Opening Pick Tool between the camera face and ring camera enclosure, and work the Opening Pick Tool around the edges to release the retention clips of the camera faceplate. The Spudger Tool can also be used to pry off the camera faceplate.

-

Remove the four PH00 screws located around the camera face. Once the four PH00 screws have been removed. Use the Spudger Tool to push the camera body loose from the ring camera enclosure. Then remove the camera body from the ring camera enclosure. This will remove the internal metal assembly that hold the camera, and PCBs.

-

-

-

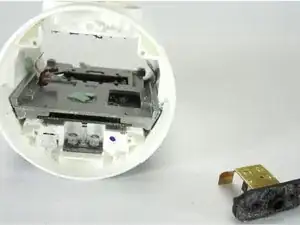

With the camera body removed from the ring camera enclosure, we can do a review of the components that make up the camera body.

-

Light Sensor

-

Camera / Camera Len

-

Multi-Color LED

-

-

-

Infrared LED Lights

-

-

-

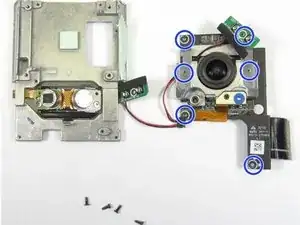

To remove the PIR Sensors, remove the two PH00 screws holding the PIR Sensor board to the Camera Body.

-

-

-

To separate the camera Lens from the Camera Sensor PCB, remove the two PH00 screws from the back of the PCB.

-

-

-

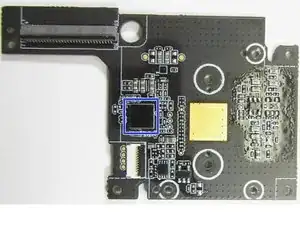

Turning our attention back to the Main System PCB removed in an early step we can see the following components that are on the backside of the PCB. The PCB is partially conformal coated.

-

-

-

-

-

-

-

-

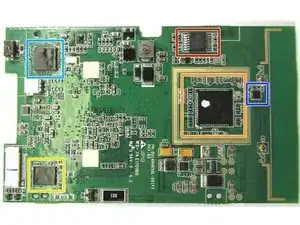

Turning our attention back to the Main System PCB removed in an early step we can see the following components that are on the frontside of the PCB. The PCB is partially conformal coated.

-

-

-

-

-

-

ES 5J SEN

-

Nordic N52832 Bluetooth 5/Bluetooth Mesh – Not listed on packaging / Product Specifications

-

-

-

Frontside close up view of the MEMS Microphone.

-

-

Backside close up view of the MEMS Microphone, which shows the Microphone port.

-

-

-

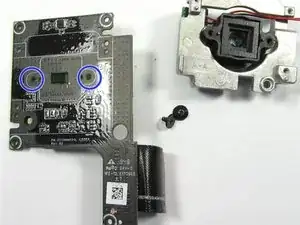

Close up view of the camera sensor board frontside

-

Image Sensor - Possibly from Omni Vision. Since Omni Vision Camera IC is used in the ring camera

-

Light Sensor

-

Multi-color LED

-

7 comments

Dude, Nice work!

Is it possible or advisable to upgrade the terrible 1080 camera lens with something better, say 4k lens?

G Mon -

Hello,

very interesting, nice work.

by any chance, do you know what sensor is the Light Sensor ? part number?

thank you.