Introduction

Motors are often used in robot vacuums and other machines. The side brush motors on your ionvac SmartClean V2 help power the spinning side brushes and maintain its optimal performance. If your ionvac has reduced cleaning efficiency, inconsistent brush functionality, or unusual noises, this may be a sign that the brush motors need to be cleaned or replaced.

This guide will show you how to replace the side brush motors and requires more time and attention to detail than other ionvac guides. You will need a Phillips #2 (PH2) screwdriver and a Jimmy tool (or another prying tool) to complete it. Remember to remove and reinstall all parts gently.

Tools

-

-

Flip your ionvac right-side up, turning it so that the front filter vents are facing forward and the power button is furthest from you.

-

-

-

Use a Phillips screwdriver to remove the 8 screws indicated in red holding the base together.

-

Use the same screwdriver to remove the 8 screws indicated in orange which hold the rims (bumper arms).

-

Remove the rims from your ionvac and set them aside.

-

-

-

Flip your ionvac right-side up and tilt it upwards at a 45 degree angle.

-

Use a Jimmy or prying tool to wedge the sharp end through the bottom crevice (below the sensors).

-

Continue prying the outside rim of your ionvac open. You will feel the top shell (frame or cover) loosen.

-

-

-

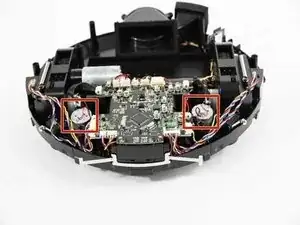

Identify the 2 side brush motors that look like cylinders on the bottom shelf of your ionvac.

-

-

-

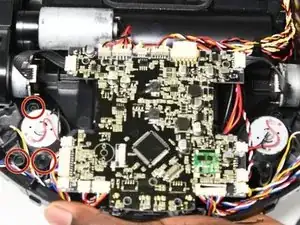

Remove the 3 screws that attach the motor to the bottom shelf.

-

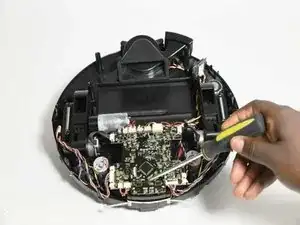

Lift the motor out of its slot.

-

To reassemble your device, follow these instructions in reverse order.