Introduction

Use this guide to remove or replace the bellows on a Wacker BS50-4AS REV 101 (2019) Vibrator/Rammer.

This model requires up to 0.7 liters of SAE 10W-40 oil to replace drained oil.

Tools

Parts

-

-

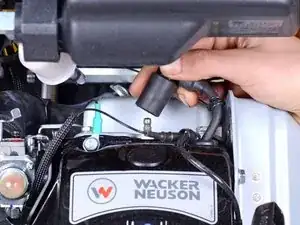

Firmly grip the base of the spark plug wire's connector and pull it away from the spark plug to disconnect it.

-

-

-

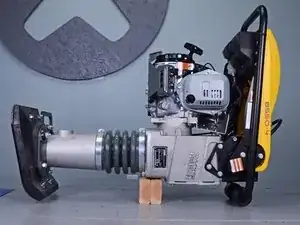

Lay the device down horizontally with the oil sight gauge facing down.

-

Position a shallow oil drain pan underneath the sight gauge.

-

-

-

Remove the oil sight gauge.

-

Let the oil drain until drips are infrequent.

-

Replace and retighten the oil sight gauge.

-

-

-

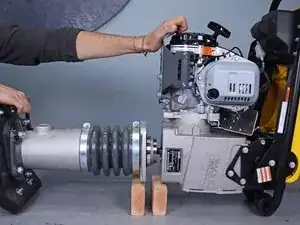

Flip the device onto the work surface such that the motor and handles face up.

-

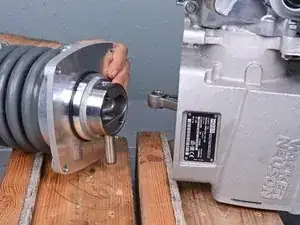

Place two separate blocks of wood underneath the seam between the leg assembly and crankcase.

-

-

-

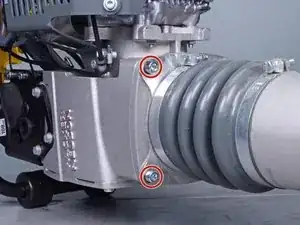

Use an 8 mm hex key socket to remove the four bolts securing the leg's guiding cylinder to the crankcase.

-

-

-

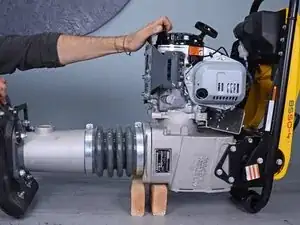

Continue to separate the two halves by compressing the bellows until the nylon plug covering the piston pin is visible.

-

-

-

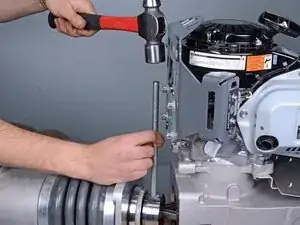

Use an appropriately-sized punch and a ball-peen hammer to tap the pin out of its hole on the guide piston until it is no longer securing the connecting rod.

-

-

-

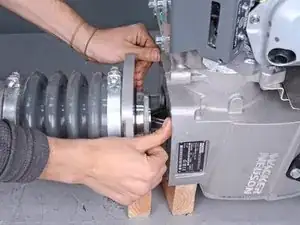

Use a 13 mm socket or large flathead screwdriver to loosen the two hose clamp bolts securing the bellows to the leg assembly.

-

-

-

Lower the bottom hose clamp away from the bellows and let it rest at the base of the leg assembly.

-

-

-

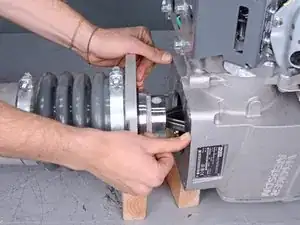

Open the top hose clamp and pull it down, past the bellows, and let it rest at the base of the leg assembly.

-

-

-

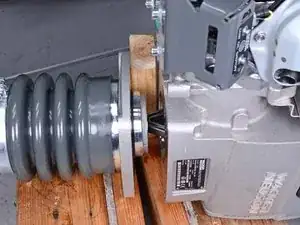

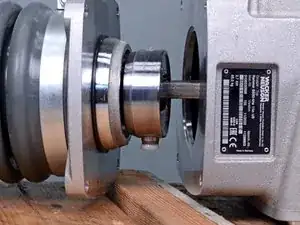

Use a rubber mallet to tap the bellows down and off of the top of the guide cylinder.

-

Once loose, pull the bellows off of the lip on the guide cylinder.

-

-

-

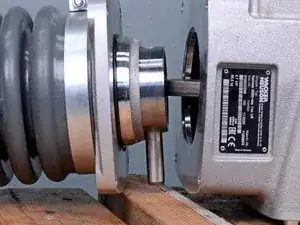

Use a rubber mallet to tap the bellows up and off of the top of the protective pipe.

-

Once loose, pull the bellows off of the lip on the protective pipe.

-

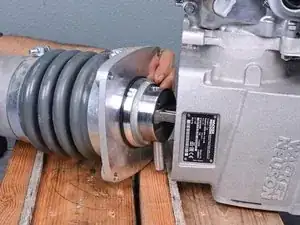

Remove the bellows.

-

To reassemble your device, follow these instructions in reverse order.

After reassembly, tilt the device upright and check the oil level through the sight glass. The oil should cover 1/2 to 3/4 of the sight glass to be considered full. This model requires up to 0.7 liters of SAE 10W-40 oil.