Introduction

The Tivoli One is a nice little radio with quite good sound and a valuable design. After long years, the station settings may no longer work, there is just a terrible scratching noise, the device is no longer usable. The cause is the - perhaps outdated - variable capacitor for the transmitter setting. It has a separating agent on the disks that was originally viscous, but dries out over time. The easiest way would be to replace the Mitsumi 2LHT-L5 type capacitor. Unfortunately it is very hard to get, Tivoli does not sell it and only with luck can you find one. The only thing left to do is to repair it. This involves disassembling and cleaning the condenser, replacing the separating agent with air. Furthermore, the components for AM wave have to be omitted, but that's not so bad, there are hardly any transmitters left.

Supplement, three months later: With this device, this complex repair has unfortunately not brought lasting success, the condition is again as before. So it can also go wrong.

Tools

Parts

-

-

Turn off the Tivoli One and disconnect the power cord.

-

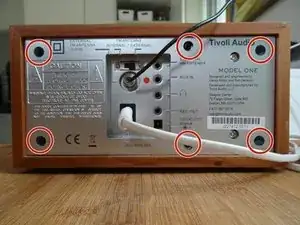

Unscrew the six #2 Phillips screws on the back panel.

-

Carefully pull out the rear panel a few centimeters, but do not remove it. It is still connected by the cables.

-

-

-

Mark the connectors on the tuner board with colored felt-tip pen so that you can plug them back in correctly later. Then pull them off

-

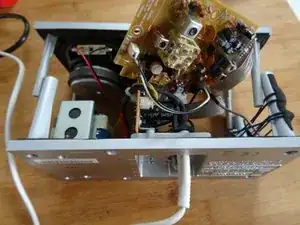

Pull out the front and the back completely.

-

-

-

Remove tuner

-

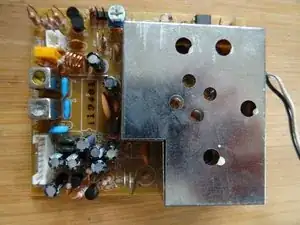

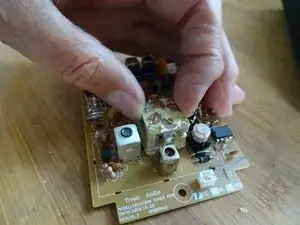

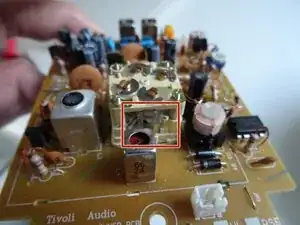

Unscrew the three Phillips screws #1 and carefully lift the tuner board upwards.

-

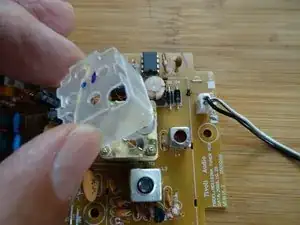

Mark the position of the coupling with a felt pen to make it easier to insert it later.

-

-

-

Detach the medium wave antenna -the black wire frame- from the back, it is no longer needed.

-

The blue VHF antenna remains. However, it is recommended to operate the device with an external antenna - a simple wire of 80 cm length is often sufficient.

-

-

-

This step is a bit tricky and tedious. Work very carefully and slowly. Mark the setting of the coupling with a felt pen.

-

Very carefully desolder the shields above the variable capacitor. Start with the flatter part on the back. There are ten solder joints on the front and back. Use a desoldering suction pump or desoldering braid. Remove the shields on the front and back.

-

-

-

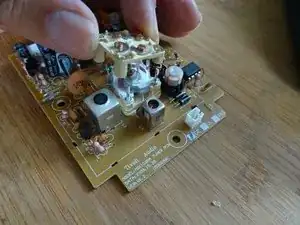

Inside the black coupling piece there is a Phillips screw. Unscrew it. Remove the circlip, it is loose.

-

Carefully pull off the black coupling piece.

-

-

-

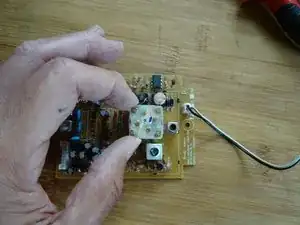

Cut through the two bars connecting the upper and lower parts of the capacitor using side cutters.

-

-

-

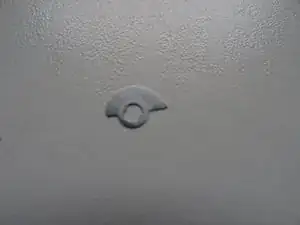

On the bottom of the top cover directly on the shaft is a small brass washer. Do not lose it!

-

Attention: Left-hand thread! Unscrew the nut on the axle clockwise.

-

-

-

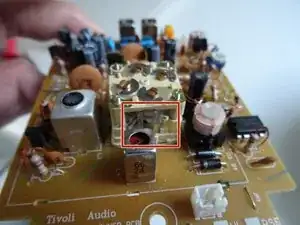

Here you can see the cause of the malfunction: the white separating agent between the plates of the capacitor has dried out. It must be removed. The lower plates are for FM, the upper ones for medium wave. The upper ones will not be needed later.

-

Slowly and patiently remove all the innards of the variable capacitor. A toothpick is good for this.

-

On the shaft are rotating rotors, fixed stators and washers. Other very small washers are on the upright posts

-

-

-

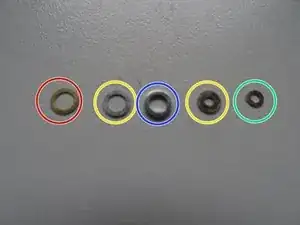

There are four different types of stators. The two shown here are still needed. They can be recognized by the long indentation at the "back" (marked red):

-

2 pieces type 1

-

2 pieces type 2

-

-

-

The two shown here are for AM and will be omitted in the future:

-

2 pieces type 3 with T-shaped eyelet on the right side

-

4 pieces type 4 with short indentation at the back

-

-

-

Here are the various washers:

-

10 pieces of brass

-

One thicker brass washer

-

various silver ones

-

some very small silver ones from the posts

-

the oval washer is not needed anymore

-

-

-

And here are the rotors. Only the type of which there are six is needed, the others are omitted.

-

-

-

Now comes the cleaning work:

-

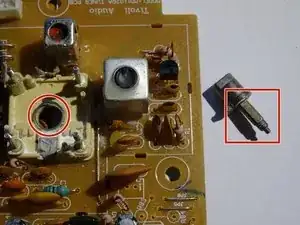

Push out the shaft. Clean the shaft and its contact ring (marked red) on the lower part of the condenser well with isopropyl alcohol, scrape off any corrosion.

-

Reinsert the shaft. The stop must be on the far right.

-

Clean the four required stators (type 1 and type 2), the six rotors and all disks well with isopropyl alcohol. Use a lint-free cotton swab for this purpose.

-

-

-

The assembly follows, work very carefully with toothpick and tweezers, do not damage the parts!

-

Place the capacitor as shown in picture 1. Start with a rotor.

-

... then a brass washer

-

Next is a stator of type 2

-

...a rotor

-

...and a brass washer

-

one of the tiny washers is put on the post.

-

-

-

Next is the next rotor, this one and the two remaining are twisted 180° against the first three rotors.

-

then a stator type 1, the stators are also twisted by 180°, then the brass disc

-

tiny disc on post

-

rotor, brass disk

-

stator type 1

-

rotor

-

thick brass disc to finish

-

-

-

Press the shaft down again.

-

The washers for the AM tuning are no longer installed and are replaced by three washers and two snap rings of size M3. Then tighten the axle nut again. Reminder: Left-hand thread so counterclockwise. Do not tighten the nut too much, light tension is enough.

-

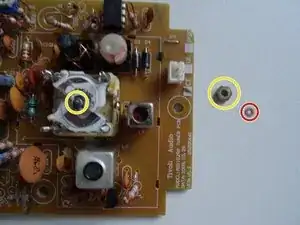

Fill the remaining washers on the two marked items

-

-

-

Put the small washer that was between the top of the condenser and the axle (see step 5) back on the axle. Oil it very lightly.

-

Carefully replace the top of the condenser. Check if the axle can be turned. Then screw the four small nuts back on, but not too tight. Always check if the axle with the rotors turns freely, maybe you have to put more spacers on the posts.

-

Put a small solder dot on the wire between the upper and lower part.

-

Replace the protective cap.

-

-

-

Make all connections between front and rear panel correctly.

-

Switch the unit to FM - you should hear at least a slight hiss. Remember the switch for the antenna on the back, an external one works better in case of doubt.

-

Adjust the variable capacitor until - hopefully - the first station can be heard - and be happy! The most important part is done.

-

Disconnect the connections again.

-

-

-

Solder the two shields again, a few solder points are sufficient.

-

Put the tuner board on and fix it with the three screws. Play a bit with the adjustment knob until the coupling fits.

-

...and connect the parts again, this time for the adjustment work.

-

-

-

The dial marked F controls the frequency. Set the dial to the frequency of a known station at about 100 MHz, use a second radio and adjust until the desired station can be heard clearly on both radios.

-

Set a weaker station at about 100 MHz and adjust with A to best volume.

-

This potentiometer allows you to adjust the LED transmitter setting to the optimum level. Set a strong transmitter and adjust the yellow LED to highest brightness.

-

Disconnect the connections between front and back part for the last time.

-

First push the front part completely into the housing, then the back part not completely.

-

Re-establish the connections and tighten the unit with the six housing screws.

-

Follow the steps in reverse order to reassemble your device

2 comments

I see that they sell Varicon capacitors for Tivoli on eBay. Maybe worth desoldering and replacing instead.

Oh yes, take advantage of this rare opportunity!

VauWeh -