Introduction

At Unterdruckbenzinhähne it can always lead to problems with the gasoline supply and leaks. That's why it should be checked and cleaned again and again. Here's a guide to the complete seal replacement on a Suzuki DR650SE SP46B. Please use original parts. (Already had problems with accessories)

Tools

Parts

-

-

The two screws, here quite funny with a large Phillips, or a 10-fork or ring spanner, unscrew.

-

Very important: The tank should be at most 1/4 full so that it does not leak. Then you can put it upright.

-

-

-

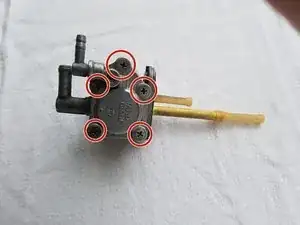

Remove the 5 membrane cover screws with Phillips PH2 and carefully remove the cover. Caution here, the diaphragm spring pops out.

-

membrane

-

diaphragm spring

-

pellicle

-

Check the seal kit and clean if necessary.

-

Now remove the diaphragm with plate.

-

-

-

Unscrew the two Phillips screws with a phillips PH2. Then remove the actuator.

-

Remove sealing plate and O-ring.

-

Steller

-

spring washer

-

cover plate

-

Now remove the foot seal.

-

-

-

membrane

-

Membrane intermediate plate

-

diaphragm cover

-

diaphragm spring

-

Fußdichtung

-

body

-

sealing plate

-

-

-

countersunk screws

-

Steller

-

spring washer

-

O-ring

-

cover plate

-

Head Screws

-

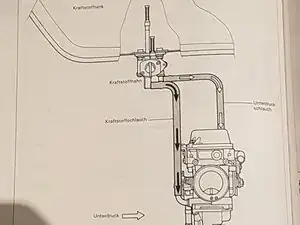

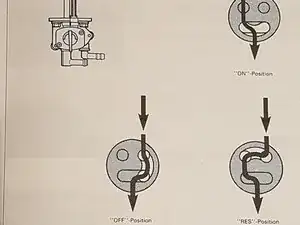

And here is a representation of how the fuel cock works.

-

-

-

Lightly grease the 3 gaskets. To remove the old seals, use the metal spudger. The new ones can be pressed in by hand.

-

sealing plate

-

and insert the O-ring into the body.

-

-

-

Thread the spring washer and the cover plate into the actuator and build it into the base body. Make sure that when screwing the spring ring is not pinched. One notices this when turning from "On" to "Res", when it comes to blocking, the spring washer is clamped. Then stop again.

-

-

-

Reinstall the diaphragm in the body.

-

Place the spring in the center of the plate.

-

When reassembling, make sure the spring is exactly in the ring on the inside of the diaphragm cover, as the lock on the other side may be misaligned.

-

-

-

Re-screw the 5 Phillips screws with a suitable Phillips screwdriver (PH2).

-

gasoline connection

-

Vacuum port

-

For functional testing, you must now apply a slight vacuum to the vacuum connection, which causes the cap to open. This can then be tested by blowing at the gasoline connection. When the vacuum drops, the shutter must close immediately.

-

Now install the foot gasket.

-

-

-

Now the fuel tap can be reinstalled.

-

Be sure to install the two sealing washers under the screws.

-