Introduction

This guide shows how to remove and replace the spray button on a Rug Doctor. The handle must be detached from the body and opened up in order to remove the button.

Tools

Parts

-

-

Use a 7/16" (11 mm OK) wrench to hold the handle axle while you use a 7/16" socket to remove the cap nut securing the axle end.

-

-

-

Support the handle with one hand. It will be loose after this step.

-

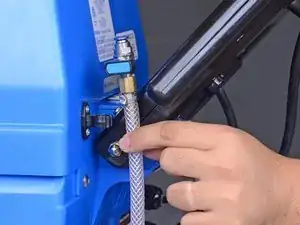

Use fingers or pliers to pull out the handle axle.

-

-

-

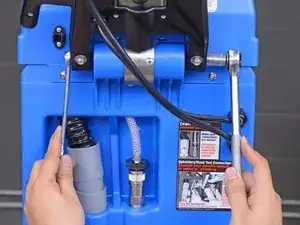

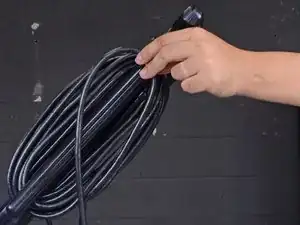

Uncoil the power cable from the handle.

-

Remove the sixteen Phillips fasteners of the following lengths:

-

Six 22.7 mm machine screws

-

Four 35.3 mm machine screws

-

Two 25.2 mm (thicker) machine screws

-

Two 48.4 mm bolts with washers

-

Two 30.1 mm screws

-

-

-

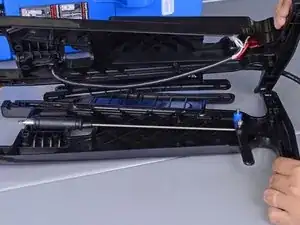

Separate the bottom edge of the handle slightly until the spring-loaded plunger pops out of its socket.

-

-

-

Use your fingers to push the black plunger down towards the bottom of the handle into position. This may take significant force.

-

Once the plunger slips into position, squeeze the the two handle halves together.

-

If that doesn't happen, check to see if the plunger is properly positioned, and that no wires are pinched.

-

Continue squeezing the two handle halves together while you reinstall the handle's lower screws.

-

-

-

Remove the two 11.4 mm long Phillips screws holding the cover plate on the handle.

-

Remove the cover plate.

-

-

-

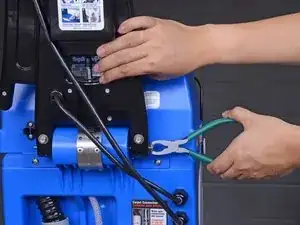

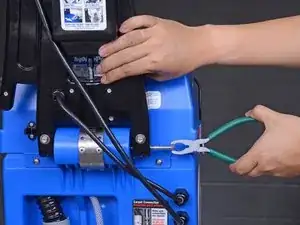

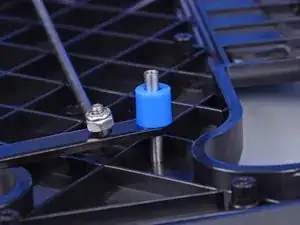

Use a pair of pliers to grasp the lip of the screw post close to the handle release lever.

-

While gripping the screw post, use a large flathead screwdriver to remove the machine screw mated to the other end of the screw post.

-

-

-

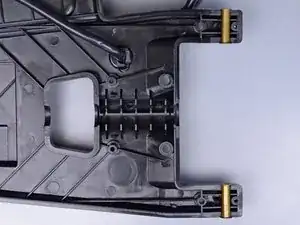

The lever mechanism components are properly stacked and oriented as shown.

-

Both brass bushings are in their sockets.

-

-

-

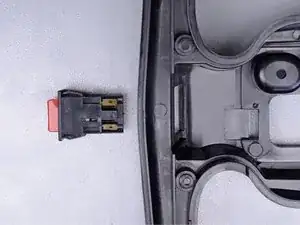

Red and black wires on the top sockets (order does not matter)

-

Two white wires on the bottom sockets

-

Use fingers or pliers to wiggle and pull the four connectors from the switch module.

-

-

-

Use fingers or wide pliers to squeeze the black retainer tabs on each side of the button module.

-

While squeezing, wiggle and push the button module out of the front of the handle.

-

Remove the button module.

-

To reassemble your device, follow these instructions in reverse order while noting the re-assembly tips.

3 comments

Remove the power cables strain relief at the handle for slack, not the 16 screws to split the handle. That takes all day and one time you will lose a screw or 2 or 4.

NICHOLAS -

could not use pliers, label was as thick as face on head, will end up replacing whole handle assembly, bad choice for fastener

JOSEPH -

cut a notch in the fastener with a dremel to get out the handle bolt

JEREMY -

Include the part number of the c shaped plate.

JAMES -