Introduction

If your grinder begins to malfunction because of gear issues, it's time to replace the grinding head assembly. The link below contains the information necessary to order a replacement from RYOBI's home webpage.

Tools

-

-

To remove the battery press down on the two buttons located on each side of the battery and pull away from the body of the grinder.

-

To remove the handle hold grinder with one hand and use the other hand to unscrew the handle with a counter-clockwise motion

-

-

-

Fully press the spindle lock button.

-

With the spindle lock button held down, use the wrench provided to loosen the clamp nut. Once loose, you can use your fingers to unscrew the nut completely

-

-

-

Remove your grinding/cutting tool by simply pulling it off the spindle.

-

Next remove the disc flange (a.k.a spacer) by pulling it off of the back end of the spindle.

-

-

-

Lift the clasp on the grinder guard. Make sure the clasp is completely loosened before proceeding.

-

Rotate the grinder guard so that the three notches on its interior align with the three slots on the grinding head assembly.

-

Once aligned, simply pull the guard off.

-

-

-

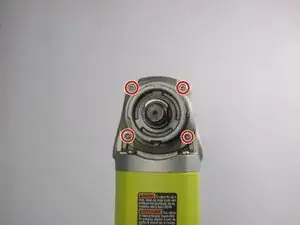

Remove the four 1.4 cm screws from the grinding head assembly using a Torx T20 screwdriver.

-

With the screws removed, the grinding head assembly can be removed from the rest of the head with a gentle pull.

-

To reassemble your device, follow these instructions in reverse order.