Introduction

Does your classic Merc have a loose shifter? Follow along as I replace the interior shifter bushes

Tools

Parts

-

-

This guide only applies to floor-shift automatics, such as my 1976 230.6 (114.015)

-

This car was never sold in USA, as I'm in New Zealand, but the centre-console is the same for all the other 114 and 115 automatics (and probably other model ranges)

-

First step is to open and remove your Ashtray to gain access to the first set of screws

-

Push down on the metal tab - while pulling the ashtray out

-

-

-

After you've removed the ashtray you'll see the ashtray frame/bracket

-

Remove the two pan-head screws at the rear of the opening - ignore the two counter-sunk screws at the bottom for now

-

Careful when you pull it out as the connector for the cigar lighter contacts on left sticks out so you can't just pull it straight-out

-

-

-

Now you can remove those two counter-sunk screws holding in the front of the shifter/center console panel.

-

-

-

The hardest, or second-hardest step

-

There is a simple metal trim clip holding the rear of the centre-console trim panel down (marked by a yellow box in photo 2)

-

You won't be able to see it easily, you can pry back the rubber trim in the marked area to gain a view of the clip (blue box area in photo)

-

In my car the plastic foot with the metal clip attached to it is cracked, so I added a small bit of wire to help pull it out next time so as not to break it (see red box in 3rd photo)

-

-

-

Ensure your handbrake is set, or you're not on a slope

-

Shift to neutral or other gears as required to get the console panel out

-

You'll need to angle the trim panel back and forth a little as the plugs for your hazards and rear defroster/demister get in the way

-

I've shown the units and their plugs in Yellow (demister) and Red (hazards)

-

-

-

It's simply clipped-in and you can pry using a small flat-head at the top to get it started

-

When you're re-installing it, you simply line up the V symbol on the shifter housing with the V symbol on the lamp holder

-

-

-

You'll need a 10mm socket - I used a 1/4in deep

-

There are 3 bolts, one on the right-side and 2 on the left

-

They have a small wavy washer, don't drop it down the centre-console when you pull them out

-

You won't be able to remove the surround fully until the next step

-

-

-

First loosen the 15mm jam nut (outlined in red)

-

Now you can unscrew the shift lever/knob

-

When you're re-installing it ensure it's clocked correctly before tightening the jam nut

-

-

-

There are four 10mm bolts, the left two bolts are hard to see, you'll need to pry the trim back a bit

-

The top-left bolt has the ground cable for the shifter backlight on it

-

The bolts have large flat washers on them, be careful not to drop them down the side of the console - use a magnet if necessary

-

-

-

After lifting up the shifter housing (black plastic part) you'll see it's attached to the shift rod below

-

The green thing in the picture is the driveshaft

-

To get better access, you can pull the shift rod towards the rear of the car (go through a few gears) as I did

-

The clip is fairly easy to remove with needle nose pliers and/or a small flat-head screwdriver

-

Be careful not to drop the clip down the side of the centre console or through the hole in the tunnel now revealed

-

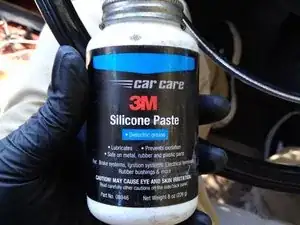

These photos are actually from re-assembly, as you can see I lubed up all bushings with 3M Silicone paste - you could use any plastic-safe lube

-

-

-

You'll see a plastic half-moon part (to stop dust and noise from entering the car) - it just pulls out

-

-

-

Remove a clip from one end of the small rod connecting the shift lever yoke to the main rod

-

Again as these photos were taken during re-assembly there is silicone lube present

-

You can see there is a tiny bushing in between the spring and the small rod on each end - these bushing are optional but cheap, mine were completely gone

-

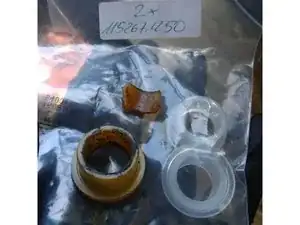

The small bushing part number is: 1152670950

-

I used a small screwdriver and needle-nose pliers to remove the clip (slide in direction of red arrow)

-

-

-

Some better views of those tiny bushings as you pull the small rod out (slide rod out in direction of arrow)

-

These photos were during re-assembly so the bushing is fresh and clear, the old ones would probably be yellowed or cracked or missing

-

I put a blue circle on one end of the small rod and a red circle on the other end so you can identify them better

-

I used again the small screwdriver and needle-nose pliers to pry the spring back while re-inserting the bushings

-

-

-

Now the hardest or second-hardest step

-

Removing the snap-ring

-

If you have small snap-ring pliers this is probably pretty easy

-

If not you might be lucky like I was and the needle-nose tips fit into the holes

-

Even so it was a challenge to install and remove the snap-ring

-

Also the part will probably go flying, so do the disassembly in a place where you can find it if it goes flying

-

The washer goes under the snap ring

-

As you can see these photos are from re-assembly, my old bushing was yellowed and the left-side in pieces

-

-

-

Finally you can slide out the main rod from the plastic housing

-

Here you'll see why you had to remove the plastic half-moon part

-

After you've got it all apart, the bushings (if any remain) should just push out

-

I cleaned up and then lubed the parts before reassembling

-

-

-

My old bushing(s) vs the new parts

-

The second image is how the bushings are oriented on the part

-

The third image is the silicone paste lubricant on the bushing, ready to be slid back into the housing

-

Follow the steps in reverse order to re-assemble

-

-

-

The main tools I used were Philips #2 screwdriver (not pictured), small flat-head screwdriver, small needlenose pliers, 10mm deep socket and drivers

-

Consumables were 3M Silicone Paste, paper towels and a bit of Brake cleaner

-

The car being worked on, an Orange Mercedes-Benz 1976 230.6 (type 114.015) with automatic transmission, in Right-hand drive as this is in New Zealand

-

To reassemble your device, follow these instructions in reverse order.

One comment

Make more /8 guides these are great!

Kaelor -