Introduction

Follow this guide to replace the lower worm shaft roller bearing on the Mantis 7940 Tiller (2017).

For this guide, you will need to use a hammer to tap out certain components that are friction fit into place. In order to do this, you will need to find a way to brace the tiller in place so it doesn’t move around during the process. You can use a vice, or have someone else brace the part while you use the hammer.

You will need replacement lithium grease for this repair.

Tools

Parts

-

-

Grab the rubber housing at the end of the spark plug wire.

-

Pull firmly to disconnect the wire from the spark plug.

-

-

-

Remove the upper handle assembly from the lower handle assembly.

-

Un-clip the throttle cable from the cable clips on either side of the handle assembly and set the upper handle assembly aside.

-

-

-

Use an adjustable wrench to turn the right half (in the orientation pictured) of the tine shaft clockwise, as shown.

-

Continue to turn the shaft clockwise until it is unthreaded from the worm gear inside the housing.

-

-

-

Use a dead blow hammer to tap the right half of the tine shaft towards the worm housing until it can be removed.

-

-

-

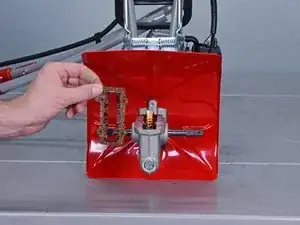

Slide the worm gear up out of the worm gear housing about 1 cm.

-

Use a flat head screwdriver to separate the right worm gear thrust washer from the worm gear.

-

-

-

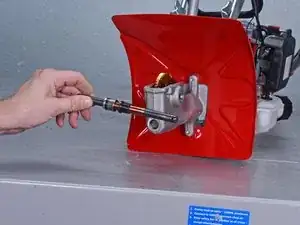

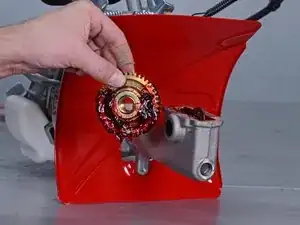

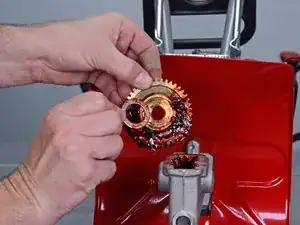

Remove the worm gear and left worm gear thrust washer from the worm housing.

-

Separate the left thrust washer from the worm gear.

-

-

-

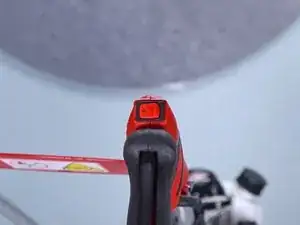

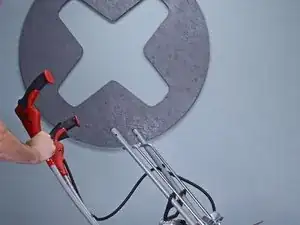

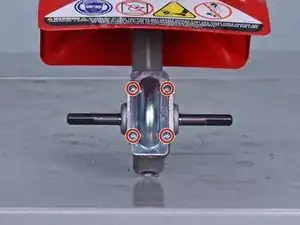

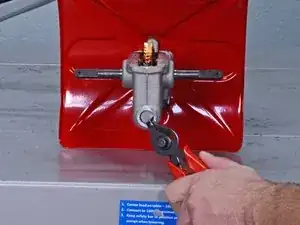

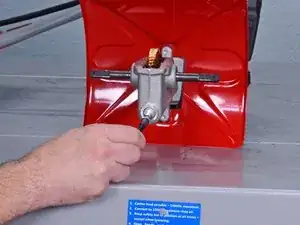

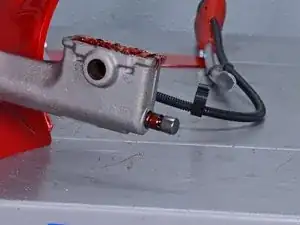

Use a pair of snap ring pliers to remove the retaining ring from the bottom of the worm housing.

-

-

-

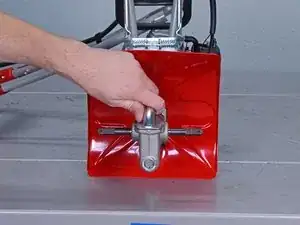

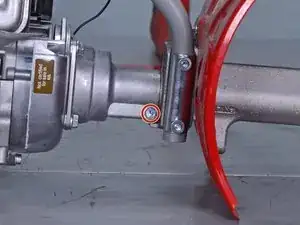

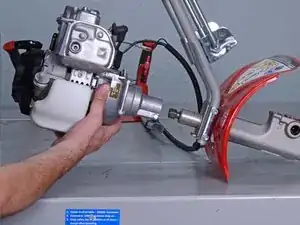

Use a socket wrench with an 8 mm socket to loosen the 3/4 inch-long flange bolt from the engine flange. It is not necessary to completely remove the flange bolt.

-

-

-

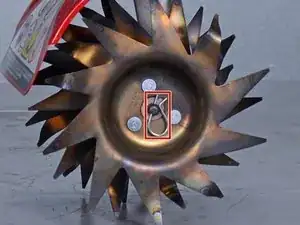

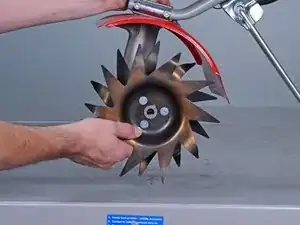

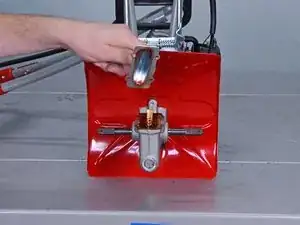

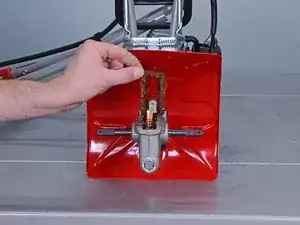

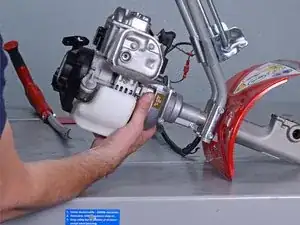

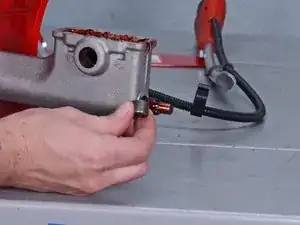

Use a dead blow hammer to gradually tap the worm shaft assembly out the bottom of the worm gear housing.

-

To reassemble your device, follow these instructions in reverse order.