Introduction

This guide is for the removal of the power board. That will allow for the board to be repaired or recapped as needed. Here is where it gets a bit Dangerous. Since this computer has a CRT there are some very High Voltages (27,000V) That means precautions will have to be taken. The CRT will have to be discharged before we can commence with any other work. For that, we can "build" a simple discharge tool. The main thing here is, that if you are not comfortable working around high voltages, or do feel slightly worried about it, don't do it. Attached to the Macintosh Classic II Back Cover Removal guide is the Apple ESD Safety Technician guide. It does have the section on CRT safety in it. Read this beforehand and make sure you understand that guide. This is at your own risk and nobody else will be responsible for any injuries or damages other than yourself. It's just a disclaimer I feel I have to make. if it is done right, it is not as dangerous as it sounds.

Tools

-

-

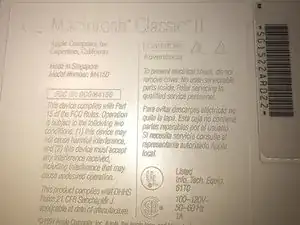

Here is one of the vintage computers in my possession. It is a Macintosh Classic II M4150. Apple considers this obsolete and " information about these products is no longer updated as of 9/1/98 "

-

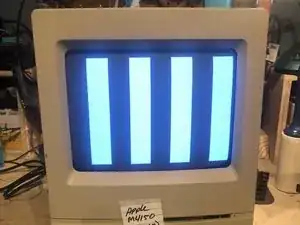

On powering it up, It originally greeted me with a checkerboard pattern that quickly converted into this pattern. The checkerboard pattern is/was commonly caused by bad Ram memory. Considering the age of this computer, leaking capacitors are a strong possibility. Time to check.

-

The cover is held in place by four (4) T-15 screws. Two (2) on the bottom

-

-

-

and two (2) under the top (handle)

-

The bottom ones are easy to remove

-

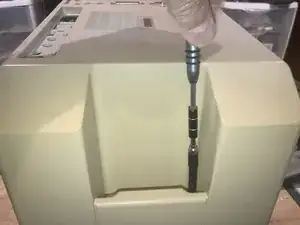

The top ones are a bit of a challenge due to the depth of the holes.

-

-

-

There was just not enough room to get a good grip on the driver.

-

Luckily this iFixit driver has a hole on the top part. I used a tool to gain some mechanical advantage. While applying downward pressure on the driver, turn the tool to the left to loosen the screw

-

Once loosened, the iFixit extension that came with my set, works perfectly to remove the screw,

-

-

-

Here are the four (4) screws. The two bottom screws are M4X15mm The top screws are those typical found in plastic to sheet metal joints.

-

With the screws removed the cover will slide off.

-

BEst practice is to lay it down and pull the case straight up. It may take some force due to the tight fit and years of storage etc.

-

-

-

Here is what the inside looks like.

-

Power supply (Sweep Board)

-

Flyback Transformer

-

Video card

-

CRT

-

SCSI Hard drive

-

Hard drive on top with the Floppy drive on the bottom

-

-

-

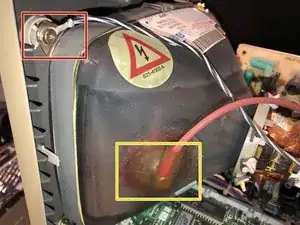

Ground screw

-

Anode Cap

-

I use a test lead I had which has Alligator clips or either end. Worked perfect for this. A piece of insulated electrical wire 18 gauge AWG (or similar) will work for this as well.

-

Next is a Flat Tip screwdriver that must italic texthave an insulated handle. No substitution allowed!

-

-

-

Connect one end of the electrical wire to the flat tip screwdriver

-

Connect the other end of the wire to the grounding screw

-

Not the sound of an explosion or anything as climactic, but definitely a cracking sound. If your CRT was discharged, maybe because it was unplugged for a awhile etc., you will not hear anything.

-

-

-

I susually make sure that the screwdriver did touch the metal and using the same precautions as before, move it on the metal for the Anode. Just to ensure it did make proper contact. Usually I wait a minute or two before withdrawing the tool.

-

The CRT is now discharged.

-

To reassemble your device, follow these instructions in reverse order.