Introduction

Tools

-

-

Wiggle the grey part of the top to remove it by pulling it towards you(away from the scroll wheel).

-

Reasoning by Jacob Hickey "because in the internal top part of the mouse where the buttons/scroll wheel is, there’s hinges-like “tooth” that’ll snap if you do pull on it. It’s like opening a jewelry box that has a hinge on one end of the box… if that makes sense…"

-

-

-

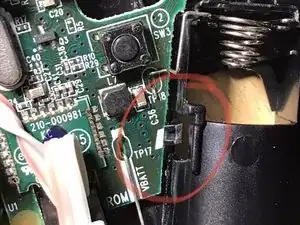

Push back small black clips to release the circuit board.

-

Slide up the metal battery connectors to free them from the casing. (Note that these are soldered to the circuit board.)

-

Fully remove the circuit board with the battery connectors and image sensor still attached.

-

-

-

Working from back to front (left to right in the first image) unclip the first two pairs of black plastic clips.

-

Slide the black upper casing forwards over the mouse wheel whilst applying pressure the two front clips to release them.

-

Separate the two casing layers fully.

-

To reassemble your device, follow these instructions in reverse order.

9 comments

Thank you Karmanyaah Malhotra for takin’ the time to do this for everybody like me :-)

were can i buy these iems telll mee please

TElll me now or else