Introduction

Application of thermal paste is essential to keep the processor cool and happy. Follow this general guide to reapply thermal paste after removing a heat sink or CPU during a repair. For more advanced directions, specific to your CPU, check out Arctic Silver's page of application methods.

To apply thermal paste to a phone, follow this guide.

Tools

-

-

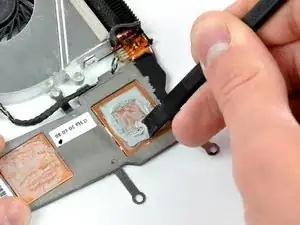

Use the flat end of a spudger to scrape off as much solidified thermal paste from the copper core(s) of the heat sink as possible.

-

-

-

Use a coffee filter or a lint-free cloth and a little isopropyl alcohol (a.k.a. IPA, 90% concentration or greater) to clean the thermal paste residue off the thermal contact surface of your heat sink.

-

Once the surface is clean, use a fresh piece of coffee filter or cloth and a little more IPA to remove any oils and prepare the surface.

-

Do not touch either the chip or the heatsink, or allow any dust or debris to get on them. Even a fingerprint can be a major obstacle to thermal transfer on a chip.

-

Allow the heat sink(s) to dry completely!

-

-

-

Use the flat end of a plastic spudger to remove any solidified thermal paste from the surface of the processor(s).

-

-

-

Again, use a coffee filter or lint-free cloth and a little IPA or ArctiClean Thermal Material Remover to clean any thermal paste residue off the processor surface.

-

Use a fresh piece of coffee filter or cloth and some IPA to remove any remaining oils and prepare the surface.

-

Allow the processor(s) to dry completely!

-

-

-

To apply new thermal paste, use the application method recommended for your specific processor type—vertical line, horizontal line, middle dot, or surface spread. Note that surface spread has the potential to trap air bubbles.

-

If you're using the surface spread method:

-

Wrap the tip of your index finger with a piece of plastic (such as a sandwich bag or Saran wrap).

-

Dispense a very small amount of thermal paste onto processor core(s).

-

Use your finger to gently smear the thermal paste over the entire processor core(s).

-

The processor(s) is now ready for heat sink installation.

-

To reassemble your device, follow your device's disassembly instructions in reverse order.

39 comments

For heat sinks with a spring on the screws: Wonder why there are springs on the heat sink screws? Do not over tighten them, the springs are there to help you apply the correct amount of pressure on to the CPU and GPU. If you tighten them all the way, it may not be the correct pressure! Leave maybe 1 mm of space, just before the screw stops turning. iFixit forgot to mention this important part, and also in the heat paste guide!!

m3kw -

This is completely untrue. The holes bored in the heat sinks are in fact a larger diameter than both the threads and the shoulder of the heat sink screws. The screws should be fully tightened (as they were from the factory) to maintain correct pressure against the processors.

I have two green lights on my xbox slim ... Should I do all of this to get rid of them? I'm not sure if they are supposed to be green. I bought my wii and remotes from a refurbishing place. I don't have the red ring of death, but I think it is from over heating.

OMG Hi -

Thank you so much for this! Have been struggling for months with CPU diode sensor reporting 262F/128C and CPU dropping to 0.8 Ghz due to Speedstep. Loosened the screws a little and the sensor is back to normal. I cannot thank you enough for this!

It didn't help my crashing MBP, NVidia bug.

gustmoge -

Try reheating / reballing the gpu soldering. It worked for me more than 3 times.

mark -

See following link: Problem with NVIDIA GeForce GT 330M 256 MB?

Greg Key -

If it was a mid 2007/early 2008 Macbook Pro 15”/17”, it is actually a GPU defect. It needs to be replaced with a revised version. In fact, dosdude1 made a video about that. If it’s a late 2008-mid 2010 15”/17” Macbook Pro, it’s actually a problem with a capacitor on the GPU buck converter circuit, it is not a problem with the GPU in these machines (C7771 on the 2008 and 2009 models, C9560 on the 2010 models.) If it’s a early/late 2011 15”/17” Macbook Pro with AMD Radeon HD 6xxxM graphics, it’s a GPU issue that can be fixed using the technique described at dosdude1.com/gpudisable.

Rupertus -

Actually, Tom's Hardware's guide said not to spread the paste out, but to have a solid line of paste vertically across the longest part of the metal cap and let the heat sink spread it out as it gets tightened. This method supposedly reduces the risk of air bubbles. My only curiousity is with processors that have little resistors or some such things placed around the metal heat cap, should those be pasted as well or not? Dell's processor came completely covered with paste, onto the chips as well, but I'm wondering if I should re-apply to the chips or just to the cap.

Frank -

Note: This old thread still deserves a reminder: Those are capacitors and the type of paste used is CRITICAL. If it is non conductive (white, pink or any non metallic color) it's Ok if it gets on the capacitors. If the recommended paste is Arctic SILVER or any metal filled paste, do NOT let it get on the capacitors. Your best bet is to apply a slim line of paste along the longest length of the chip and use a credit card as a squeegee to spread the paste into a smooth film. Then apply a small drop to the center (optional). Wetting the surface helps.

airyu -

the best way to clean a CPU or a GPU is to use a spudger and ISOPROPYL its an alcohol that dries fast

USE WITH CAREFULLY DO NOT DRINK OR USE IT FOR ANY OTHER PURPOSE.

YOU CAN USE ISOPROPYL TO CLEAN WOUNDS OR CPU'S OR GPU'S

ISOPROPYL

What is isopropyl

Ronald -