Introduction

Follow this guide to disassemble and rebuild a leaky or clogged pump for the Graco Paint Sprayer, model 17C325.

Note: The pump’s rebuild kit comes with four black leather packing O-rings. Soak them in a cup of SAE 30 motor oil for an hour before installing them in the pump.

As you disassemble the pump, take the time to clean all the parts with soap, water, and a brush before reassembly, and replace any worn-out parts as needed, which are provided in the pump repair kit (part # 18B260).

Tools

Parts

-

-

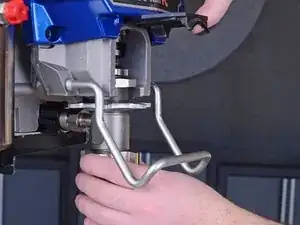

Use your fingers to unscrew and loosen the connector securing the hose to the pump.

-

Once unscrewed, push the connector back to reveal the hose connection.

-

-

-

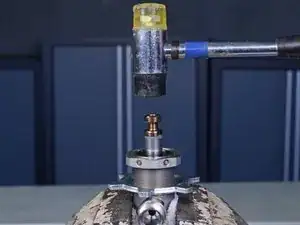

Place the pump cylinder into a vise.

-

Use a flathead screwdriver and mallet to unscrew and loosen the top jam nut.

-

-

-

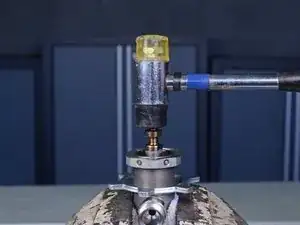

With the pump cylinder still in the vise, use a mallet to gently tap down on the top of the piston rod to loosen it from the pump cylinder.

-

-

-

Remove the pump cylinder from the vise and pull the bottom of the piston rod completely out of the pump cylinder to remove it.

-

-

-

Use your fingers to grab and remove the white plastic gland from the top of the pump cylinder.

-

-

-

Flip the pump cylinder upside down and use a flathead screwdriver and mallet to gently tap the throat packing O-rings, loosening them from the cylinder.

-

-

-

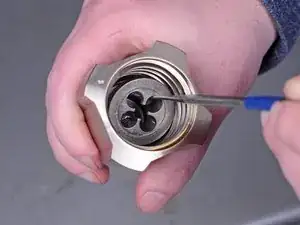

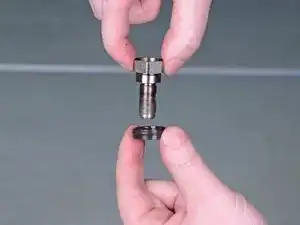

Use a 3/4" wrench to remove the piston valve bolt from the piston rod.

-

Remove the piston valve bolt from the piston rod.

-

To reassemble your device, follow these instructions in reverse order.