Introduction

This guide demonstrates how to remove or replace the left lower feeder assembly in the auto-feeder on your Electric Eel 75’ Drain Cleaner Z5K12IC75AF.

If you need to remove or replace the right lower feeder assembly, simply perform steps 12-17 on the opposite side of the feeder body.

Tools

Parts

-

-

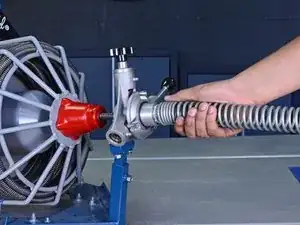

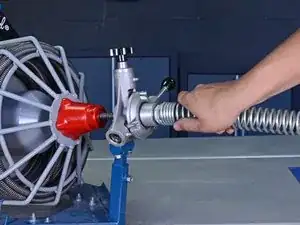

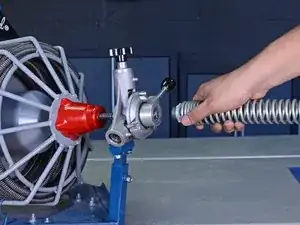

Twist the guide spring counter-clockwise to unscrew it from the auto-feeder.

-

Remove the guide spring.

-

-

-

Set the feeder adjustment knob in the neutral position, in between the "FWD" and "REV" positions.

-

-

-

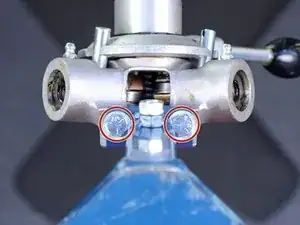

Use a 1/2" open-ended wrench to remove the two bolts from the bottom of the feeder body mounting arm.

-

-

-

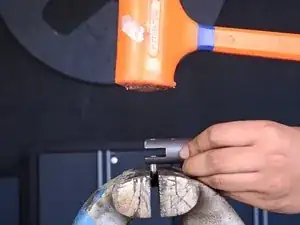

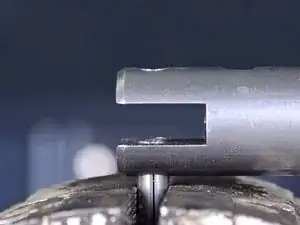

Use a dead blow hammer or mallet to tap down the bearing carrier onto the roll pin until the pin just begins to peek into the bearing channel.

-

-

-

Continue to tap down the bearing carrier until the bearing and spacer are fully secured around the roll pin.

-

-

-

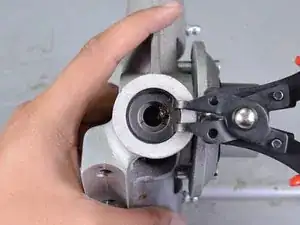

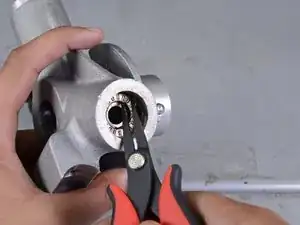

Use a pair of snap ring pliers to remove the retaining ring at the bottom of the lower feeder assembly.

-

-

-

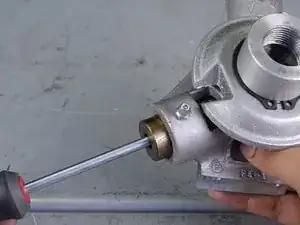

Use a flathead screwdriver or other long tool as leverage to remove the lower bearing carrier from the assembly.

-

To reassemble your device, follow these instructions in reverse order.

After reassembly: Ensure the assembly you just installed is sufficiently lubricated using the Zerk fitting on the feeder body.