Introduction

Follow this guide to replace the head assembly on a EDCO Disk Grinder model 50200-HD.

This repair requires two people.

Tools

Parts

-

-

Ensure the machine is unplugged.

-

Turn the power switch counterclockwise into the OFF position.

-

-

-

Slide the motor towards the front of the machine as far as it will go to loosen the belt tension.

-

Use a 9/16 inch socket to tighten the four bolts back down to lock the motor in a position where there's the least belt tension.

-

-

-

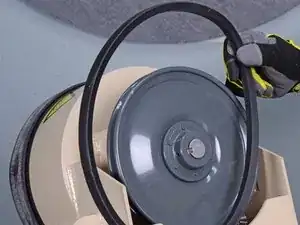

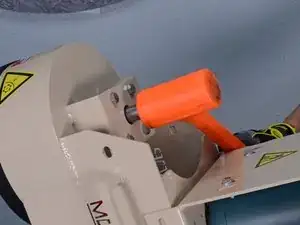

Pinch a flathead screwdriver between the belt and sheave.

-

Rotate the sheave and pivot the belt up and away from its groove.

-

-

-

Continue to rotate the sheave with once hand while holding the flathead screwdriver with the other to fully dislodge the belt from the groove.

-

-

-

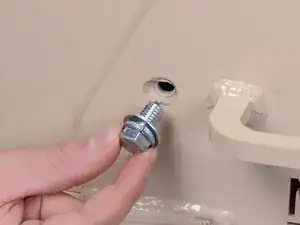

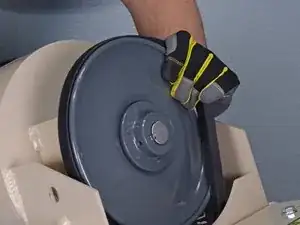

Use a 5/32 inch hex wrench to loosen the set screw securing the sheave to the head assembly shaft.

-

-

-

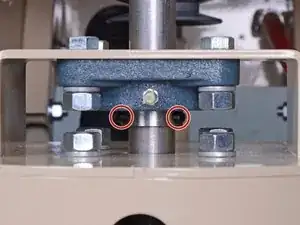

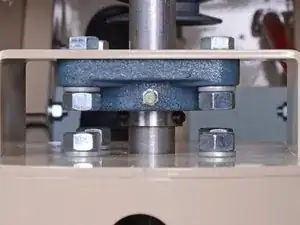

Use a 5/32 inch hex bit with an extension to loosen the two set screws securing the head assembly shaft to the upper bearing.

-

-

-

Use a 5/32 inch hex bit with an extension to loosen the two set screws securing the head assembly shaft to the lower bearing.

-

-

-

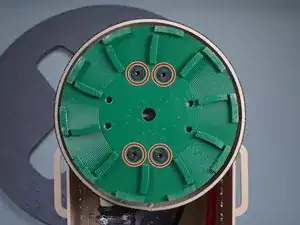

Use a 7/32 inch hex key to remove the four flat screws securing the disk to the head assembly.

-

-

-

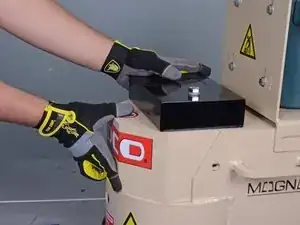

Use a dead blow hammer to hit the head assembly shaft straight down until it is flush with the upper bearing bracket, or as far as it will go.

-

-

-

Insert the new head assembly up into the bearing as far as you can by hand.

-

Use a dead blow hammer to knock the head assembly up into the machine until there is no play in the shaft spacer.

-

To reassemble your device, follow these instructions in reverse order.

One comment

i have a leveler nob that feels seized. any advise would help

DUSTIN -