Introduction

This guide will show you the necessary steps to replace the motor in your Dyson DC14 Vacuum. This is a lengthy process; you should set aside a good amount of time to finish this guide in one attempt.

Tools

Parts

-

-

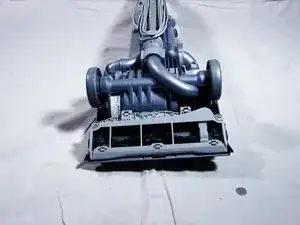

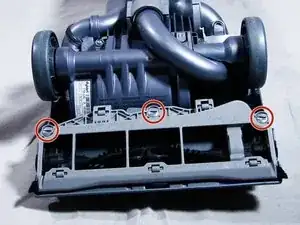

Using a quarter, turn the three soleplate fasteners 90 degrees to the left.

-

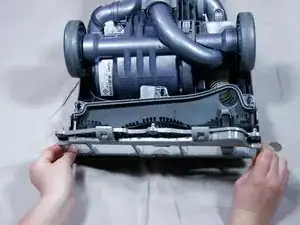

Holding the soleplate on both sides, tilt it down and away from the vacuum.

-

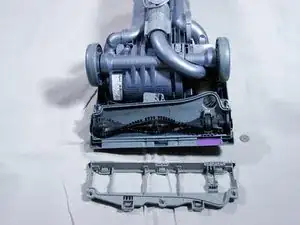

Remove the soleplate from the vacuum.

-

-

-

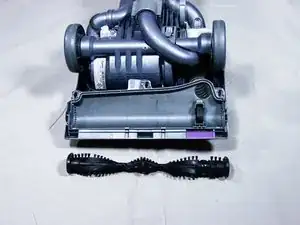

Turn down the squared tabs on the brushbar so that they face outward.

-

Use a screwdriver to pry the belt up from the brushbar.

-

While holding the belt, pull the brushbar to the left and remove it from the vacuum.

-

-

-

Place vacuum upright, with the canister facing you.

-

Remove the canister, setting the canister aside.

-

-

-

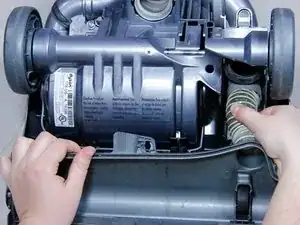

Insert flathead screwdriver under each latch and pry up gently.

-

Open the cover, remove the exhaust filter, and set the filter to the side

-

-

-

Place vacuum face down.

-

Remove the u-bend pipe that connects the canister to the telescopic wand.

-

-

-

Pull the clear hose out of the gasket on the right side of the vacuum under the axle.

-

Pull the hose straight back towards you.

-

-

-

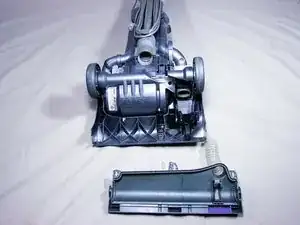

Remove brush-bar housing by prying the housing out of the clips that hold it.

-

Pull brush-bar housing toward you while keeping vacuum stationary.

-

-

-

Pull the cover of the brush clutch belt out towards you.

-

Pull belt to the right to remove the belt from the brush clutch axle.

-

-

-

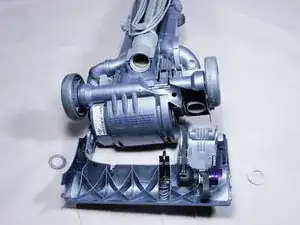

Insert a flat-head screwdriver into the two locking rings to remove the rings, which are located above the wheels on both sides.

-

These rings secure the bottom assembly of the vacuum to the rest of the unit.

-

-

-

Remove the four T15 torx screws that secure the motor housing to the vacuum.

-

Remove the elbow-bend pipe on the right-side of the vacuum.

-

Press the two release latches on either side of the elbow-bend pipe. Pull it out and away from the vacuum.

-

-

-

Place the vacuum right-side up and leave it standing up.

-

Remove the right side cover by pushing the release latch down while lifting the cover towards you.

-

-

-

Insert flat head screwdriver between gray motor housing and black motor.

-

Pry motor cover housing away.

-

-

-

Release the motor assembly from its housing by strongly hitting the brush clutch axle with a hammer.

-

-

-

Remove the power terminals from both sides of the motor.

-

Remove the motor from the housing completely.

-

To reassemble your device, follow these instructions in reverse order.

12 comments

Rather than use a screwdriver for belt removal & risk injury or machine damage, why not use the proper belt tool ?. It saves time & possible injury and is available for not much more than the cost of a decent quality flat head screwdriver.

Andy -

Motor works beater bar does not turn

What if its not the motor

Great guide! A useful tip for getting the motor (or specifically the rubber cover) into the motor case: smear some washing up liquid or liquid soap around the inside of the motor case, and the rubber will slip in a lot easier. Keep an eye nf the rotational position of the motor (so that it fits the hole at the axle end correctly), and make sure you don't trap the 2 power wires.

Some models don't have the clutch mechanism, but are driven directly from the motor (and the belt cover which is shown as the clutch cover is now part of the soleplate); in that case, it may be simpler to just remove the belt from the motor spindle.

If you've had the vacuum cleaner more than 2 or 3 years, consider changing the belt at the same time, they are not expensive

Paul Blitz -