Introduction

This guide shows how to remove and replace the wheel drive motor on the Barreto Tiller E1320 2016.

Tools

Parts

-

-

Flip the ignition switch to the OFF position.

-

Ensure the wheel drive control lever is set to the neutral position.

-

-

-

Pull the locking pin out and rotate it 90˚ to unlock the right wheel from the hub.

-

Repeat for the left wheel.

-

-

-

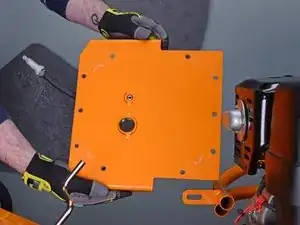

Use a 9/16 inch socket and wrench to remove the two bolts and accompanying nuts securing the engine guard to the tank lid, one on each side.

-

-

-

Use a shop towel to clean and remove any remnants of silicone gasket material from the top of the lid and surrounding areas.

-

-

-

Place an oil drain pan underneath the wheel drive motor to catch hydraulic fluid that will spill out during this procedure.

-

-

-

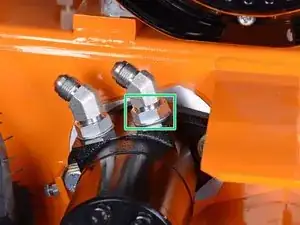

Use an adjustable wrench to loosen the nut securing the lower fluid hose to the fitting on the wheel motor.

-

-

-

Remove the lower fluid hose from the wheel motor.

-

Allow residual fluid in the hose to drip into the drain pan underneath the motor.

-

-

-

Use an adjustable wrench to loosen the nut securing the upper fluid hose to the fitting on the wheel motor.

-

-

-

Remove the upper fluid hose from the wheel motor.

-

Allow residual fluid in the hose to drip into the drain pan underneath the motor.

-

-

-

Place paper towels into the hose openings to block residual fluid from dripping as you continue the procedure.

-

-

-

Use an adjustable wrench to loosen the nut locking the upper hose fitting to the wheel motor.

-

-

-

Use an adjustable wrench to loosen the nut locking the lower hose fitting to the wheel motor.

-

-

-

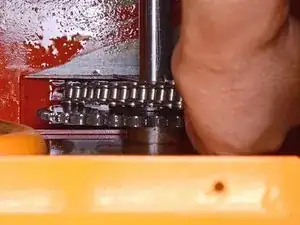

Use a 7/16 inch wrench to loosen the tensioner bolt's lock nut.

-

Back the tensioner bolt out about 1/2 inch.

-

-

-

Use a 3/4 inch socket and breaker bar to remove the two bolts securing the wheel drive motor to the frame.

-

-

-

Tighten down both motor mounting bolts until there is no gap between the spacer and the frame or between the motor and the spacer.

-

-

-

With the motor loose, rotate it 90˚ counterclockwise and push it as far left as it will go to give the drive chain some slack.

-

-

-

Reaching in from the top of the tank, lift the drive chain up and off of the axle gear.

-

Remove the chain from the wheel drive motor sprocket.

-

-

-

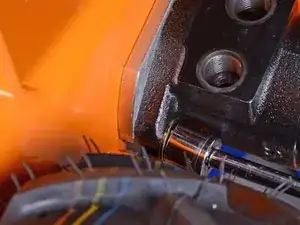

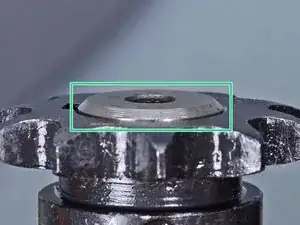

Use a 5/32 inch hex key to loosen the set screw securing the sprocket to the wheel motor shaft.

-

-

-

Remove the sprocket from the wheel motor shaft.

-

Align the top face of the sprocket with the end of the shaft's chamfer.

-

Only the motor remains.

-

To reassemble your device, follow these instructions in reverse order.

One comment

When putting back together I found it helpful to put the chain on the motor sprocket first. Then partially on the wheel drive sprocket and roll the unit

ARIEL -