4

1

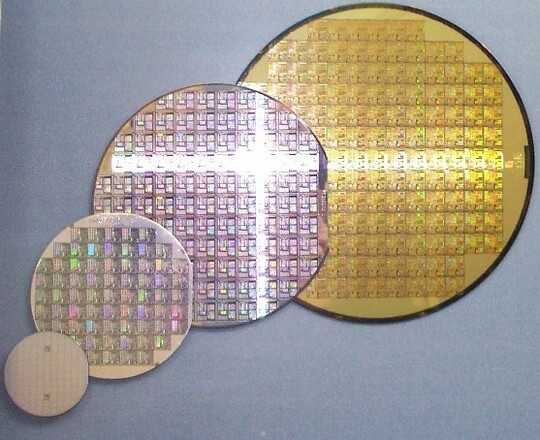

When manufacturing chips, circular silicon wafers are cut into dies of needed size:

The goal of this challenge is maximizing the number of whole dies that can be cut from a wafer of a given diameter.

The machine puts the wafer into an angular compartment:

_____________________

| xxxxxx

| xxxxxxxxxxxx

| xxxxxxxxxxxxxx

|xxxxxxxxxxxxxxxx

|xxxxxxxxxxxxxxxx

| xxxxxxxxxxxxxx

| xxxxxxxxxxxx

| xxxxxx (this ascii art is meant to be a perfect circle)

It measures a distance dx from the left edge, and makes a vertical cut. Then it makes the needed number of additional vertical cuts, with spacing of the needed width. It makes the horizontal cuts in the same way: first one at a distance dy, and then with spacing of height.

The material remains perfectly still during the cutting: it's not allowed to move some slices of material before making the perpendicular cuts.

The machine has a stepper motor that works at absolute accuracy but can only go integer-sized distances.

Make a program or a subroutine that gets (or reads) the following parameters:

- Wafer

diameter - Die

width - Die

height

and outputs (or prints)

dx- horizontal starting positiondy- vertical starting position

such that the number of rectangular dies is maximal.

Some fine points:

- If a corner of a die lies exactly on the circumference of the circle, the die is considered usable (rectangular)

- No edge cases: you can assume that the wafer's diameter is even; at least one die can be cut out; also make other reasonable assumptions

- All sizes are integer numbers of millimeters; maximum wafer diameter is 450

Shortest code wins!

P.S. The code must finish running in a reasonable amount of time, e.g. over a weekend (2 days) - for wafer diameter equal to 300.

P.P.S. If there are several different output values that are optimal, the code must output one of them - no need to output all of them!

Test cases:

Wafer diameter 8, die size 2 x 2 => dx = 0, dy = 1 (6 dies)

Wafer diameter 20, die size 5 x 4 => dx = 1, dy = 2 (10 dies)

Wafer diameter 100, die size 12 x 12 => dx = 9, dy = 3 (41 dies)

Wafer diameter 300, die size 11 x 11 => dx = 7, dy = 7 (540 dies) - a realistic example

Wafer diameter 340, die size 15 x 8 => dx = 5, dy = 2 (700 dies) - a Pythagorean triple

Wafer diameter 300, die size 36 x 24 => dx = 2, dy = 6 (66 dies) - full-frame sensors

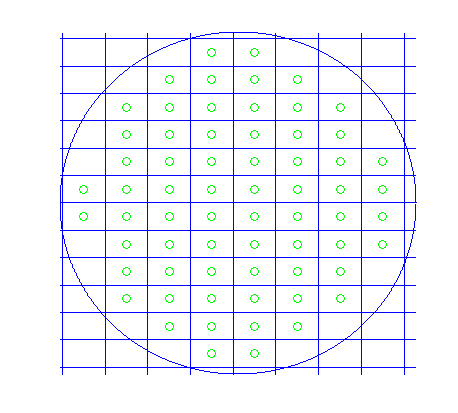

Here is a visualization of the last test case:

Must finish in a reasonable time for what input bounds? – feersum – 2015-06-24T18:49:00.557

I thought the answers to these questions were obvious; added a clarification anyway. – anatolyg – 2015-06-24T18:55:42.333

Bloody hell, over a weekend?! Who has the patience to test that... – Beta Decay – 2015-06-24T18:59:19.537

Can you provide some test cases? – BrainSteel – 2015-06-24T19:04:44.007

@BetaDecay 2 days is just an upper limit to allow brute-force solutions using languages that are unsuitable for this task. It's OK if your code runs much faster (maybe less than 1 second). – anatolyg – 2015-06-24T19:04:58.430

@AlexA. The sizes of the dies are parameters to the function/program. I guess this counts as "fixed". – anatolyg – 2015-06-24T19:19:11.267

Ugh, sorry. Brain flatulence. – Alex A. – 2015-06-24T19:22:27.180

Must dx and dy be rounded to integers before calculating the number of dies? This might result in sub optimal die counts... – agtoever – 2015-06-25T08:19:07.187

@agtoever

dxanddyare integers (the question specifies this, really) – anatolyg – 2015-06-25T08:58:46.357